Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

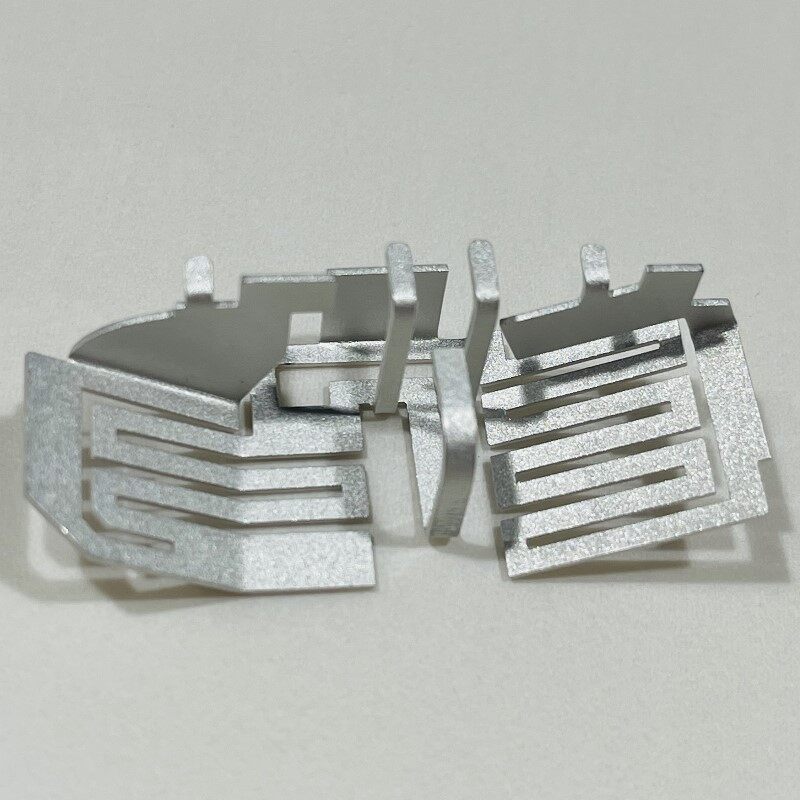

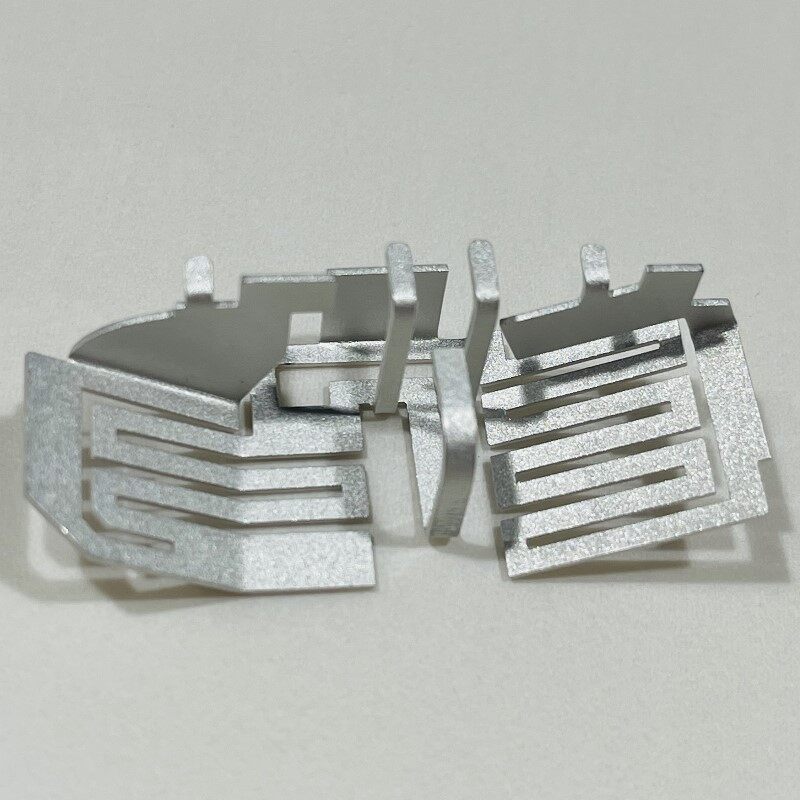

The Evolution and Benefits of OEM CNC Plasma Cutting Service Suppliers

In today’s dynamic manufacturing world, precision and efficiency are paramount. Whether you're in aerospace, automotive, or any other industry requiring exact cuts and shapes, OEM CNC plasma cutting service suppliers play a crucial role. But what exactly makes these suppliers indispensable, and why should you consider partnering with them? Let’s dive into the fascinating world of OEM CNC plasma cutting and explore how these suppliers make a difference.

What Is CNC Plasma Cutting?

Before we delve into the specifics of OEM CNC plasma cutting service suppliers, it’s essential to understand what CNC plasma cutting entails. CNC, or Computer Numerical Control, refers to the automation of machine tools through the use of computers. Plasma cutting, on the other hand, is a process that uses a plasma torch to cut through electrically conductive materials. By combining these technologies, CNC plasma cutting offers precise, fast, and efficient cutting solutions.

The Role of OEM CNC Plasma Cutting Service Suppliers

OEM, or Original Equipment Manufacturer, CNC plasma cutting service suppliers are companies that provide custom cutting services for various industries. These suppliers use CNC plasma cutting technology to produce high-quality parts and components according to the specifications provided by their clients. Here’s a closer look at the benefits they offer:

1. Precision and Accuracy

One of the most significant advantages of OEM CNC plasma cutting service suppliers is their ability to deliver precise and accurate cuts. With advanced CNC technology, these suppliers can produce complex shapes and intricate designs with minimal deviation from the desired specifications. This precision is crucial in industries where even the slightest error can lead to costly mistakes or safety issues.

2. Customization

Every project is unique, and OEM CNC plasma cutting service suppliers understand the need for customization. They work closely with clients to tailor their services to specific requirements, whether it’s the type of material, thickness, or design complexity. This level of customization ensures that the final product meets the exact needs of the client, enhancing the overall quality and functionality.

3. Efficiency and Speed

Traditional cutting methods can be time-consuming and labor-intensive. CNC plasma cutting, however, allows for rapid and efficient processing of materials. OEM suppliers leverage this technology to deliver quick turnaround times without compromising on quality. This efficiency can be particularly beneficial in industries with tight deadlines or high production demands.

4. Cost-Effectiveness

While the initial investment in CNC plasma cutting technology can be substantial, it often proves to be cost-effective in the long run. OEM CNC plasma cutting service suppliers offer competitive pricing due to their streamlined processes and reduced waste. By cutting materials precisely and efficiently, they minimize material wastage and labor costs, ultimately providing better value for clients.

5. Versatility

OEM CNC plasma cutting service suppliers are not limited to a single type of material or application. They can work with various metals, including steel, aluminum, and stainless steel, and cater to a wide range of industries. This versatility makes them a valuable partner for businesses with diverse cutting needs.

How to Choose the Right OEM CNC Plasma Cutting Service Supplier

Selecting the right OEM CNC plasma cutting service supplier is crucial for ensuring the success of your project. Here are some factors to consider:

1. Experience and Expertise

Look for suppliers with a proven track record and extensive experience in CNC plasma cutting. Their expertise will ensure that they can handle complex projects and deliver high-quality results.

2. Technology and Equipment

The quality of the cutting service depends significantly on the technology and equipment used. Choose suppliers who invest in the latest CNC plasma cutting machines and maintain them regularly.

3. Customer Reviews and Testimonials

Check customer reviews and testimonials to gauge the supplier’s reputation and reliability. Positive feedback from previous clients can provide valuable insights into the supplier’s performance and customer service.

4. Turnaround Time and Pricing

Discuss the expected turnaround time and pricing with potential suppliers. Ensure that their timelines align with your project schedule and that their pricing is competitive without compromising on quality.

5. Support and Communication

Effective communication and support are essential for a successful partnership. Choose suppliers who are responsive and willing to work closely with you throughout the project.

The Future of OEM CNC Plasma Cutting Services

As technology continues to advance, OEM CNC plasma cutting service suppliers are expected to evolve as well. Innovations in automation, artificial intelligence, and materials science will further enhance the capabilities of CNC plasma cutting. Suppliers will likely offer even more precise, efficient, and cost-effective solutions, driving the industry forward.

In conclusion, OEM CNC plasma cutting service suppliers play a vital role in modern manufacturing by offering precision, customization, efficiency, and versatility. By partnering with the right supplier, businesses can benefit from high-quality cutting services that meet their specific needs. As technology progresses, these suppliers will continue to adapt and provide cutting-edge solutions, ensuring that they remain indispensable in the ever-evolving manufacturing landscape. So, whether you’re looking to cut metal for aerospace parts or automotive components, OEM CNC plasma cutting service suppliers are your go-to partners for excellence and innovation.