Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

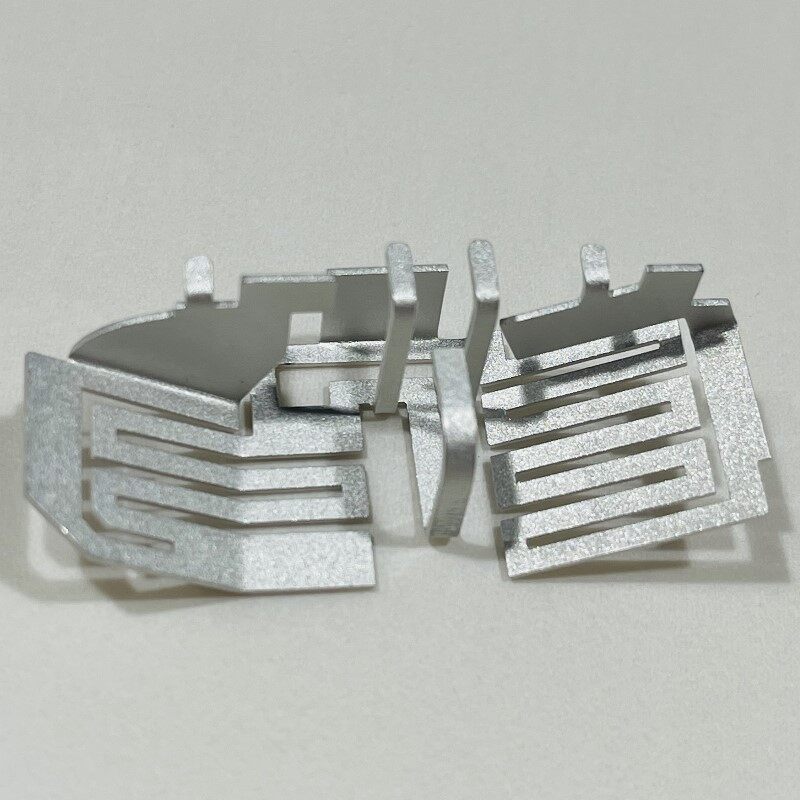

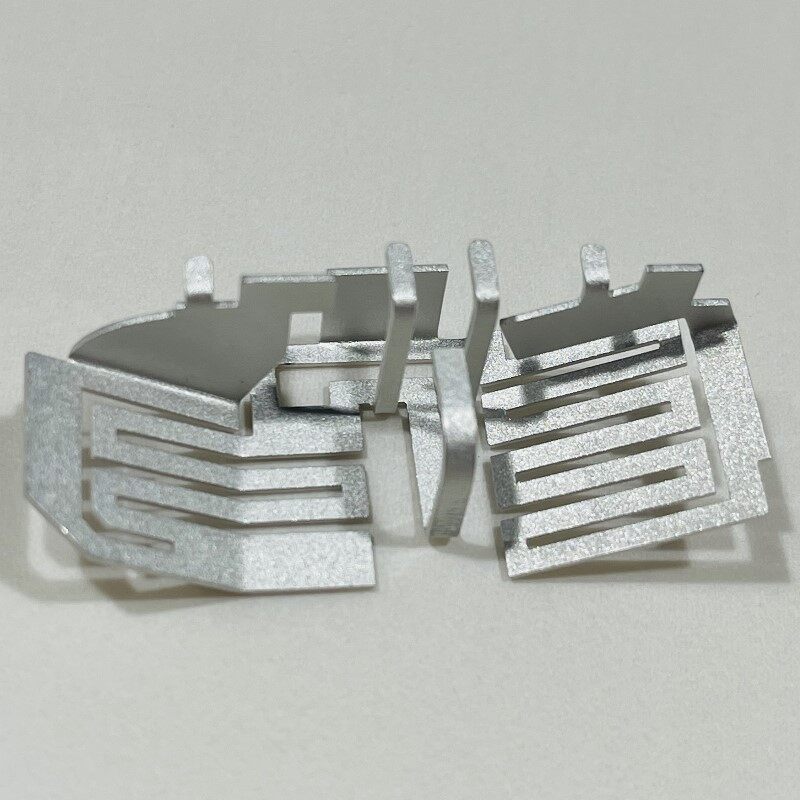

Choosing the Best OEM CNC Plasma Cutting Service Company: A Simple Guide

CNC plasma cutting is widely used in manufacturing. It helps create precise parts from different metals like steel and aluminum. Many companies now turn to OEM CNC plasma cutting service companies to get the parts they need. These companies offer custom solutions for different projects. In this guide, we will explain what CNC plasma cutting is, why you might need an OEM service, and how to choose the best service for your needs.

What Is CNC Plasma Cutting?

CNC plasma cutting is a process that uses a plasma torch controlled by a computer to cut metals. The torch creates a high-temperature plasma arc that melts and blows away the metal. This makes it easier to cut through thick metals. The "CNC" part means the process is automated, which allows for more precision.

Why Choose an OEM CNC Plasma Cutting Service Company?

1. Precision and Quality

One of the main reasons is the high level of precision. CNC plasma cutting can make very accurate cuts. This is important when you need parts that fit exactly as designed. The machines cut the material in the right shape and size every time, reducing mistakes.

2. Customization

Another reason is customization. When sourcing OEM CNC plasma cutting services, many companies need parts made to specific sizes or shapes. The company can work with you to create parts that match your exact requirements. Whether you need a unique design or specific tolerances, a good service provider will help you achieve the results you need.

3. Speed and Efficiency

CNC plasma cutting is fast. The process can cut materials quickly, which helps you get your parts sooner. When you choose the company, you can often get your order faster than if you did it in-house. The automated process also reduces the need for manual work, which speeds up production.

4. Cost-Effectiveness

It can be cheaper to outsource your plasma cutting to the company. Buying and maintaining CNC plasma cutting machines can be expensive. By outsourcing, you can save money on equipment, training, and maintenance. Instead, you pay for the service you need when you need it, without the added costs of owning the machines.

How to Choose an OEM CNC Plasma Cutting Service Company

When you are sourcing OEM CNC plasma cutting services, it is important to choose the right company. Here are a few things to consider when making your decision:

1. Experience

Look for a company with experience in CNC plasma cutting. The more experienced the company, the better they will be at delivering high-quality results. An experienced company knows how to handle different types of materials and projects. They will also know how to fix problems if they come up.

2. Equipment and Technology

Check the equipment the company uses. The technology they have will affect the quality of the work. A good company uses the latest machines and software. Modern equipment helps ensure better accuracy and faster cutting speeds.

3. Material Options

Different metals and materials require different cutting methods. Not all CNC plasma cutting machines can handle every type of material. Make sure the company can cut the materials you need, whether it’s steel, aluminum, or other metals. The company should have the equipment and knowledge to work with your materials.

4. Turnaround Time

Time is important in manufacturing. When sourcing OEM CNC plasma cutting services, you want to know when your parts will be ready. Make sure the company can meet your timeline. A reliable company will give you a clear idea of how long the work will take and keep you updated if anything changes.

5. Cost

While you want quality, you also want to keep costs in check. When sourcing OEM CNC plasma cutting services, get quotes from different companies. Compare prices, but also consider the quality of the work and the speed of delivery. Make sure the price is reasonable for the level of service you are getting.

How Sourcing OEM CNC Plasma Cutting Services Works

Here’s a simple overview of how the process works when sourcing OEM CNC plasma cutting services:

1. Request a Quote

First, you will contact the company and provide details about your project. You will need to tell them the materials, sizes, and quantities of parts you need. The company will give you a quote based on this information.

2. Design and Prototyping

Once you agree to the quote, the company will start the design process. If needed, they will create a prototype of the part to make sure everything fits correctly. This step helps to catch any problems before full production begins.

3. Production

After the design is approved, the company will start the actual cutting process. Using CNC machines, they will cut the material according to the design. They will check the work as they go to make sure everything is accurate.

4. Inspection and Delivery

Before shipping, the parts will be inspected to make sure they meet the required standards. Once everything is ready, the company will ship the parts to you. Many OEM CNC plasma cutting service companies can also offer extra services like finishing or coating if needed.

Long-Term Benefits of Working with an OEM CNC Plasma Cutting Service Company

1. Reliable Quality

When you work with the same company over time, you can count on consistent quality. The company will become familiar with your needs, making it easier to get the parts you need on time and with the right quality.

2. Better Pricing

As your business grows and you place larger orders, you may be able to get discounts. A long-term partnership with the company can help lower your costs over time.

3. Expert Advice

Working with the same company for a long time means you can get advice from their experts. They can help you choose the right materials, designs, and cutting methods. This can improve the overall quality of your parts and save you time.

Conclusion

Finding the right OEM CNC plasma cutting service company can make a big difference in the quality and cost of your parts. It’s important to choose a company that has the experience, technology, and ability to handle your materials. By considering these factors, you can ensure that your project will be completed on time and with high precision.