Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How CNC Machining Works and Helps Industries

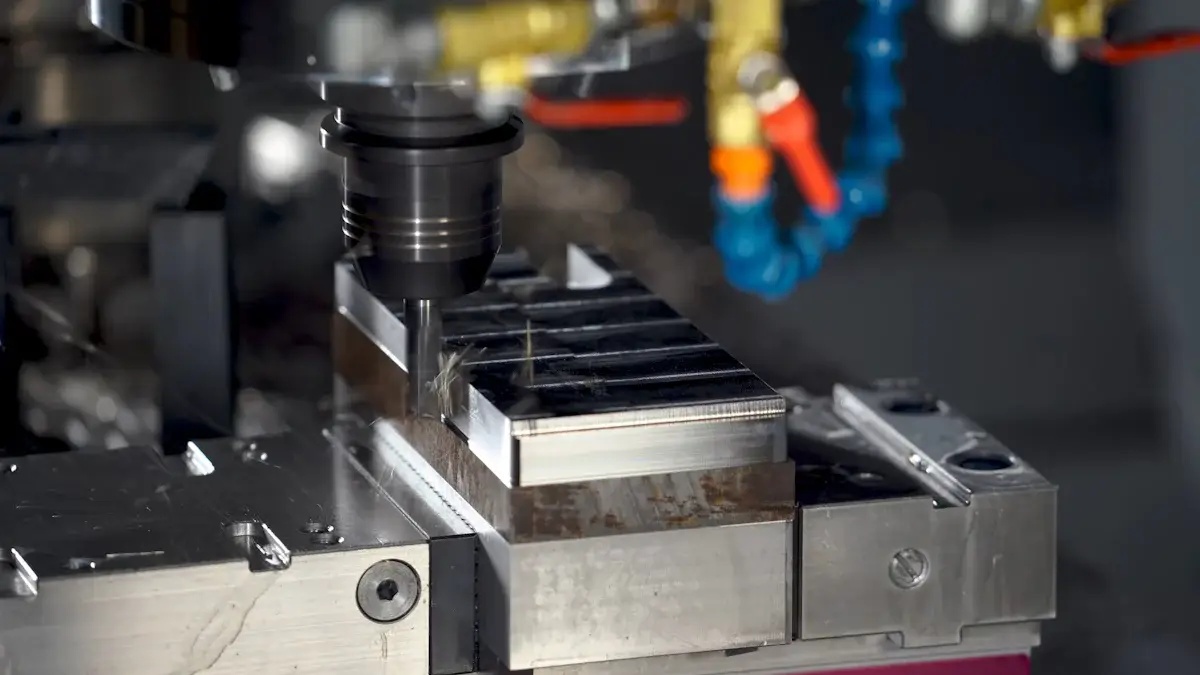

CNC machining uses smart machines to shape materials very precisely. It helps turn raw materials into finished parts by cutting away extra material. This process removes human mistakes and gives the same results every time. It has changed manufacturing, making it quicker and better. Companies now work faster and more accurately with CNC machining. It can handle tricky designs and keep exact details, making it key to modern production.

Key Takeaways

-

CNC machining automates the shaping of materials with high precision, reducing human error and ensuring consistent results.

-

The process involves designing parts digitally, converting them to G-code, and using machines to cut or shape materials accurately.

-

CNC machining is beneficial for industries like automotive, aerospace, and healthcare, providing speed, cost savings, and the ability to create complex designs.

-

Automation in CNC machining enhances safety by minimizing human interaction with dangerous tools and reducing the risk of accidents.

-

The integration of AI and IoT is transforming CNC machining, making it smarter and more efficient through real-time monitoring and data analysis.

-

Sustainability practices in CNC machining, such as using recyclable materials and energy-efficient machines, are becoming increasingly important for reducing environmental impact.

-

CNC machining is suitable for both large-scale production and custom projects, offering flexibility and adaptability to meet diverse industry needs.

What Is CNC Machining?

Definition and Overview of CNC Machining

CNC machining means Computer Numerical Control machining. It uses computers to guide machines in shaping materials. A program, often written in G-code, gives the machine instructions. The machine follows these steps to cut, drill, or shape the material. It removes extra material until the final shape is ready. Unlike doing it by hand, CNC machining is more accurate and reliable.

This process works with many materials like metal, plastic, and wood. It can make simple items or very detailed parts. Its ability to do tasks automatically makes it important for modern factories.

Key Features That Differentiate CNC Machining from Traditional Methods

CNC machining has features that make it different from older methods. First, it uses automation. The computer runs the machine, so no manual work is needed. This lowers mistakes and saves time. Second, it is very precise. The machine follows exact measurements to make perfect parts.

Another feature is repeatability. Once programmed, the machine can make the same part over and over. Older methods often can’t match this consistency. CNC machining also handles complex designs. It can create detailed shapes that are hard to make by hand.

Benefits of CNC Machining in Modern Manufacturing

CNC machining has many advantages for today’s factories. One big benefit is speed. Automated machines finish tasks faster than people can. This helps companies meet deadlines and make more products. Another benefit is saving money. While setup costs may be high, less labor and waste save money over time.

CNC machining is also flexible. You can change designs quickly by updating the program. This is great for custom orders or testing new ideas. It’s also safer because machines do most of the work, reducing risks. Lastly, CNC machining supports creativity. It works with tricky designs and materials, helping to make advanced products.

The Role of Computer Programming and G-code

CNC machining uses computer programs to control machines. Special software writes instructions in G-code. This code tells the machine how to move and cut. Each line of G-code gives a specific command. It controls speed, direction, and cutting depth.

You don’t need to guide the machine by hand. The program runs everything automatically. This makes the process accurate and consistent. If you want to change a design, you just update the code. This makes CNC machining great for simple or detailed projects.

Step-by-Step Process of CNC Machining

CNC machining follows clear steps. Here’s how it works:

-

Design the Part: First, you make a digital model using CAD software. This is the plan for the part.

-

Convert to G-code: Next, the CAD file is turned into G-code using CAM software. This creates the machine’s instructions.

-

Set Up the Machine: Then, you place the raw material on the machine. Aligning it properly ensures good results.

-

Load the Program: After that, you upload the G-code to the machine. This gets it ready to work.

-

Run the Machine: The machine starts cutting or shaping the material. It removes extra material to form the part.

-

Inspect the Part: Finally, you check the part for accuracy. Small fixes can be made if needed.

This process is efficient and precise. You can repeat it to make identical parts without mistakes.

Automation and Precision in CNC Operations

Automation is important in CNC machining. Once the program is loaded, the machine works on its own. This reduces the need for supervision. Automation also lowers mistakes, improving product quality.

Precision is another big advantage. The machine follows exact measurements for every cut. It can make very tiny adjustments, even less than a millimeter. This is crucial for industries like aerospace and medical devices.

CNC machining combines automation and precision. It handles complex designs and keeps results consistent every time.

CNC Controller and Its Role

The CNC controller is like the machine's brain. It reads the program and turns it into movements. This helps the machine follow the exact path, speed, and depth from the G-code. Without it, the machine wouldn’t know what to do.

Think of the controller as a team leader. It makes sure the spindle, motors, and other parts work together. It also checks for mistakes during the process. If something goes wrong, it can stop the machine or fix the issue. This makes the controller very important.

Tools Used in CNC Machines (Like Lathes, Mills, and Routers)

CNC machines use different tools to shape materials. Each tool has a special job. For example:

-

Lathes: These spin the material while cutting it into shapes. They are great for making round parts like pipes.

-

Mills: These cut material by moving a spinning tool over it. Mills are good for flat surfaces or detailed shapes.

-

Routers: These are like mills but work better with soft materials. They are perfect for making fancy designs in wood or plastic.

Each tool is guided by the CNC controller for accuracy. You can switch tools to do many tasks in one project. This makes CNC machines useful for many jobs.

Software and Programming in CNC Machining

Software is key in CNC machining. It helps design parts, write code, and control the machine. Two main types of software are:

-

CAD Software: This is used to draw digital models of parts. Programs like AutoCAD help create detailed designs.

-

CAM Software: This turns CAD designs into G-code. CAM programs like Fusion 360 make sure the code fits the machine.

Programming languages like G-code and M-code are also important. G-code controls movements, while M-code handles extra tasks like turning the spindle on. Learning these codes helps you adjust and fix the machine.

With software and programming, you control every step. This ensures each part is made exactly as planned.

Sensors and Feedback Systems for Accuracy

Sensors and feedback systems are very important for CNC machining. They act like the machine's "eyes and ears," watching and listening to its work. These systems help keep the machine accurate by making small fixes. Without them, it would be harder to get the same results every time.

How Sensors Work in CNC Machines

Sensors gather live data about how the machine is working. They check things like position, speed, heat, and vibration. For example:

-

Position Sensors: These watch where the cutting tool and material are. They make sure the tool stays on the right path.

-

Force Sensors: These measure the pressure during cutting. If the pressure gets too high, the machine can stop or adjust to avoid damage.

-

Temperature Sensors: These check how hot the tool and material get. If it gets too hot, the machine can slow down or cool the area.

Sensors collect this data to help the machine stay accurate and avoid mistakes.

The Role of Feedback Systems

Feedback systems use sensor data to fix problems while the machine works. This is called a "closed-loop system." Here’s how it works:

-

Data Collection: Sensors send information to the CNC controller.

-

Analysis: The controller checks the data against the program.

-

Adjustment: If something is wrong, the controller fixes the machine's movements.

For example, if the tool moves off course, the feedback system notices and corrects it. This keeps the final product matching the design perfectly.

Benefits of Sensors and Feedback Systems

These systems offer many benefits:

-

Better Accuracy: They catch tiny mistakes, so every cut is perfect.

-

Same Quality Every Time: They keep parts consistent, which is great for mass production.

-

Less Waste: By avoiding errors, they save materials and money.

-

Improved Safety: Sensors spot problems like overheating or too much pressure and stop the machine before damage happens.

Why These Systems Matter

If you use CNC machining, sensors and feedback systems make sure your work is reliable. They help turn your designs into real parts exactly as planned. Whether you’re making one item or thousands, these tools ensure top quality and precision.

Types of CNC Machines

CNC machines come in different types for specific jobs. Knowing about them helps you pick the right one. Below are three common types and what they do.

CNC Milling Machines and Their Uses

CNC milling machines use spinning tools to cut materials. They are great for making flat surfaces, grooves, and detailed shapes. These machines create parts with high accuracy and complex designs.

In factories, CNC milling machines are used in car and airplane industries. They make engine parts, molds, and custom models. These machines work with metals, plastics, and wood. They can switch tools, making them perfect for projects with many steps.

CNC Lathes for Round Parts

CNC lathes shape materials by spinning them against a cutting tool. They are best for making round or even parts. You can use them to create pipes, shafts, and rings.

CNC lathes are common in car and plumbing industries. They make exact parts, even in large batches. With automatic controls, they give smooth finishes and precise sizes without extra effort.

CNC Plasma and Laser Cutters for Exact Cuts

CNC plasma and laser cutters use powerful beams to cut materials. Plasma cutters are good for metals like steel and aluminum. Laser cutters can cut wood, plastic, and thin metals.

These machines are useful in building, sign-making, and jewelry work. They are great for detailed designs and smooth edges. Their accuracy reduces waste and ensures perfect cuts every time.

CNC 3D Printers for Additive Manufacturing

CNC 3D printers build objects by adding material in layers. Unlike older CNC machines, they don’t cut material away. Instead, they create parts by stacking material. This method, called additive manufacturing, makes complex shapes possible.

How CNC 3D Printers Work

CNC 3D printers follow simple steps:

-

Design the Model: First, make a 3D digital model using CAD software. This acts as the printer’s guide.

-

Slice the Model: Next, slicing software splits the model into thin layers. Each layer is a small part of the final object.

-

Load the Material: Then, load the printer with plastic, resin, or metal powder.

-

Print the Object: The printer adds material layer by layer to match the design. It moves carefully to stay accurate.

-

Post-Processing: Finally, clean, polish, or cure the printed part for finishing.

This process is easy to follow and very flexible.

Benefits of CNC 3D Printers

CNC 3D printers have many advantages for modern manufacturing:

-

Complex Designs: They make detailed shapes and hollow structures that other methods can’t.

-

Material Efficiency: They use only what’s needed, so there’s less waste.

-

Customization: You can change designs to make unique or special items.

-

Rapid Prototyping: They let you test ideas quickly before making large batches.

-

Wide Material Range: They work with plastics, metals, and even ceramics.

These features make CNC 3D printers great for innovation.

Applications of CNC 3D Printers

CNC 3D printers are used in many fields because they are so useful:

-

Healthcare: They make prosthetics, dental tools, and surgical equipment.

-

Aerospace: Engineers use them for lightweight, strong parts.

-

Automotive: They help design car parts and custom accessories.

-

Education: Schools use them to teach design and engineering skills.

-

Consumer Goods: Companies make custom jewelry, phone cases, and more.

These examples show how CNC 3D printers are changing industries.

Why CNC 3D Printers Matter

CNC 3D printers turn ideas into real objects with accuracy and creativity. They save material, work fast, and allow new possibilities. Whether you’re an engineer, artist, or hobbyist, these printers help you create and solve problems in exciting ways.

How CNC Machining Helps Different Industries

Making Cars: Prototypes and Large-Scale Production

CNC machining is very important in making cars. It helps create test models for new car designs. These models let engineers check ideas and improve them before making the final product. CNC machines make sure every test model is exactly like the design.

For making many parts, CNC machining keeps quality the same. It makes engine parts, gears, and other important pieces with great accuracy. This ensures all parts fit together perfectly, reducing mistakes during assembly. CNC machining also speeds up production, helping car makers meet deadlines.

Airplanes and Defense: Exact and Strong Parts

In airplanes and defense, accuracy is a must. CNC machining makes parts with extreme precision, meeting strict rules in these fields. Airplane engines, landing gear, and frames depend on CNC machining for safety and performance.

CNC machines can also make parts that are light but strong, which is important for planes and spaceships. They work well with metals like titanium and aluminum, perfect for these uses. In defense, CNC machining creates weapons, radar parts, and other key tools with high reliability.

Medical Tools: Custom and Clean Parts

The medical field needs special tools and clean processes. CNC machining is great for both. It makes custom implants, surgical tools, and prosthetics designed for each patient. This helps patients heal better and ensures a perfect fit.

CNC machining also keeps parts clean during production. It reduces human handling, lowering the chance of germs. Materials like stainless steel and safe plastics are used, making parts strong and safe for the body. Whether making one custom tool or many, CNC machining ensures accuracy and cleanliness.

Electronics and Consumer Goods: Small Parts Made Perfectly

CNC machining is key for making small, detailed parts. These parts are used in electronics and everyday items. CNC machines are great because they are precise and consistent. They make sure every piece, like a phone part or appliance piece, is made exactly right.

How CNC Machining Helps Electronics

Electronics need perfect parts to work properly. Even tiny mistakes can cause problems. CNC machining avoids this by making parts with high accuracy. It creates things like circuit boards, connectors, and casings that fit perfectly. It also works well with delicate materials like aluminum and copper, keeping them strong and precise.

For example, CNC machines make heat sinks for laptops and gaming consoles. These help control temperature. They also make protective housings for sensors and microchips. With CNC machining, electronic devices stay reliable and work well.

Uses in Consumer Goods

CNC machining helps make high-quality products for daily use. It’s used to design and create items like kitchen tools, watches, and fitness trackers. These products are made with great detail and care. CNC machines can also add special touches, like engraving logos or patterns on surfaces.

For example, they can carve designs into metal or plastic, making items look fancy. They also help produce large batches of identical parts. This keeps products consistent and builds trust with buyers.

Why CNC Machining is Useful

CNC machining has many benefits for these industries:

-

Precision: Every part is made to exact measurements.

-

Material Options: It works with metals, plastics, and more.

-

Scalability: It handles both small and large production runs.

-

Customization: Designs can be changed easily for special orders.

With CNC machining, companies can make creative, high-quality products that meet customer needs.

Construction and Architecture: Creative and Accurate Designs

CNC machining has changed how buildings and structures are made. It helps create custom designs and patterns with great accuracy. Raw materials are turned into beautiful and useful parts for construction.

Making Unique Building Features

CNC machines bring creative ideas to life. They carve detailed patterns and shapes into materials like wood, stone, and metal. This helps make custom walls, panels, and decorations for buildings.

For example, CNC routers can cut fancy designs into wooden panels for walls or ceilings. CNC milling machines can shape stone or concrete into columns or sculptures. These features make spaces look special and stylish.

Saving Time in Construction

CNC machining makes construction faster and more efficient. It creates parts like beams and brackets with exact sizes. This means pieces fit together perfectly, saving time and reducing waste.

Prefabricated parts, like walls and floors, benefit from CNC machining. Each piece is made to match, making assembly quick and easy. This also makes buildings stronger and safer.

Why CNC Machining Helps Construction

CNC machining offers many advantages:

-

Creative Freedom: It allows for unique patterns and shapes.

-

Consistency: Every piece matches the design perfectly.

-

Material Choices: It works with wood, stone, and metals.

-

Time Efficiency: It speeds up production and reduces manual work.

Using CNC machining in construction helps create strong, beautiful, and precise structures.

Why CNC Machining is Helpful for Industries

Making Accurate and Reliable Parts

CNC machines make parts that match exact designs every time. They follow clear instructions, so there are no mistakes like with hand tools. This means you can trust them to make high-quality parts, even in big batches. Every cut or shape is done perfectly, no matter how tricky the design.

This accuracy is very important for detailed work or tight measurements. For example, airplane and medical industries need precise parts to work safely. CNC machining ensures every piece is made right, building trust in the products.

Saving Money on Big Projects

CNC machining helps save money in the long run. Setting it up might cost more at first, but it saves money later. The machines work on their own, so you need fewer workers. They also waste less material because they cut very carefully.

For making lots of parts, CNC machines are very useful. Once set up, they can keep working without stopping, making the same part over and over. This helps finish projects on time and keeps costs low. Using CNC machining makes production faster and more affordable.

Easy Changes for New Ideas

CNC machining is great for testing new ideas or making custom parts. You can quickly change the machine’s program to try different designs. This lets you test shapes, sizes, and materials without wasting time.

For special orders, CNC machines can make unique parts easily. Whether it’s a new design or a small change, the process is fast and accurate. This flexibility helps create new products and stay ahead in industries that need constant updates.

Better Safety and Fewer Mistakes

CNC machining makes factories safer by using machines to do risky jobs. It reduces the need for people to work near sharp tools or heavy equipment, lowering the chance of accidents.

How CNC Machines Keep You Safe

-

Less Contact with Dangerous Tools

CNC machines work on their own after setup. You just load the material and press start. This keeps you away from sharp blades and spinning parts. -

Safety Features Built In

New CNC machines have safety tools like emergency stop buttons and covers. Sensors can stop the machine if something goes wrong, keeping you and the machine safe. -

No Heavy Lifting

Manual work often means lifting or holding heavy items. CNC machines handle this for you. Your job is to program and watch the process, not strain your body.

Fewer Mistakes in Manufacturing

CNC machines follow exact instructions, so they don’t make the same mistakes people do. The program controls every move, ensuring the machine sticks to the design perfectly.

-

Same Results Every Time

Once programmed, the machine makes identical parts again and again. It doesn’t get tired or distracted, so there are no differences. -

Fixing Problems Quickly

Sensors check the machine’s work as it happens. If something is wrong, the machine stops or adjusts to fix it. This keeps the final product accurate.

Why Safety and Accuracy Are Important

When workers are safe and mistakes are rare, factories run better. CNC machining gives you reliable results while protecting people. That’s why it’s so important in today’s industries.

Challenges and Future Trends in CNC Machining

Common Challenges in CNC Machining (e.g., High Initial Costs)

CNC machining is precise and efficient but has some challenges. One big issue is the high starting cost. Buying CNC machines needs a lot of money. Advanced models with more features cost even more. For small businesses, this can feel too expensive.

Another problem is finding skilled workers. CNC machines do many tasks automatically, but experts are needed to program and fix them. Hiring trained people can be hard. Teaching current workers takes time and money too.

Material waste is also a concern. CNC machines cut away material to shape parts. This creates leftover scraps, especially with costly materials like titanium. Managing this waste is very important.

Lastly, machine breakdowns can slow work. CNC machines need regular care to run well. If one stops working, fixing it can take time and delay projects. Planning maintenance and having backup machines can help avoid problems.

Integration of AI and IoT in CNC Advancements

The future of CNC machining is exciting with AI and IoT. AI helps improve programming by studying data and making better cutting paths. This saves material and boosts efficiency. AI can also spot problems early, so you can fix them before machines stop working.

IoT connects CNC machines to a network for live monitoring. Sensors collect data on how machines are running and if tools are wearing out. You can check this data from anywhere, making management easier. IoT also helps with maintenance. It warns you when parts need fixing, avoiding sudden breakdowns.

These tools also make teamwork better. Cloud platforms let you share designs and updates quickly. This speeds up work and keeps everyone informed. AI and IoT are making CNC machining smarter and more connected.

Sustainability and Eco-Friendly Practices in CNC Machining

CNC machining is focusing more on being eco-friendly. Many industries now aim to lower their impact on the planet. You can use green methods to make your work better for the environment.

One way is by using recyclable materials. Metals like aluminum and steel can be reused, cutting down waste. Using biodegradable coolants and oils also reduces pollution. These are safer for workers and nature.

Energy-saving is another focus. New CNC machines use less power than older ones. Switching to energy-efficient machines can reduce your carbon footprint. You can also use solar panels or other renewable energy sources to power your shop.

Cutting waste is important too. Smart software plans cuts to leave less scrap. Leftover materials can be used for other projects. These steps help the planet and save money over time.

By choosing eco-friendly practices, you help the environment while keeping CNC machining precise and efficient.

CNC machining changes how things are made in industries. It uses precise cutting and automation to create parts. This technology is used in cars, planes, and healthcare tools. It is fast, accurate, and flexible, making it important for factories today. As industries grow, CNC machining will help make better designs faster. New ideas like AI and IoT will make it even smarter and greener. Using CNC machining keeps you ready for changes and ahead of others in a busy world.

What is CNC machining, and how does it work?

CNC machining means using computers to control machines for shaping materials. You first design the part on a computer. The machine follows a code, called G-code, to cut or shape the material. This process makes sure the part is accurate and consistent.

What materials can CNC machines work with?

CNC machines can work with many materials. These include metals like steel, aluminum, and titanium. They also handle plastics, wood, foam, and composites. The material you pick depends on what your project needs, like strength or flexibility.

How accurate are CNC machines?

CNC machines are very precise. They can make parts with tiny errors, as small as 0.001 inches. This accuracy is important for industries like aerospace, medical tools, and electronics, where exact sizes are needed.

Is CNC machining suitable for small businesses?

Yes, small businesses can use CNC machining. The machines cost a lot at first, but they save money later by reducing waste and labor. Small businesses often use them for custom parts, testing ideas, or small production jobs. Outsourcing CNC work is another way to save money.

What industries benefit the most from CNC machining?

Many industries use CNC machining. Car companies make engine parts and test models. Airplane makers use it for light, strong parts. Doctors rely on it for implants and tools. Electronics companies use it for tiny, detailed pieces. Builders also use it for creative designs.

Can CNC machines create complex designs?

Yes, CNC machines are great for tricky designs. They follow exact instructions to make detailed shapes and patterns. Whether it’s carvings, curves, or hollow parts, CNC machines can do it. This makes them useful for both creative and technical projects.

How does CNC machining compare to 3D printing?

CNC machining and 3D printing are different. CNC machining cuts material to shape it, while 3D printing adds layers to build it. CNC is better for hard materials and high precision. 3D printing is good for testing ideas and making lightweight designs. Choose based on your project.

Do CNC machines require skilled operators?

Yes, skilled workers are needed for CNC machines. Operators must know how to program, set up, and fix the machine. Learning G-code and design software is important. While machines do most of the work, people ensure everything runs smoothly.

How can CNC machining reduce production costs?

CNC machining saves money in many ways. Machines do most tasks, so less labor is needed. They cut materials carefully, so there’s less waste. They also work fast, helping finish projects quickly. Over time, these savings make up for the high starting cost.

What are the future trends in CNC machining?

CNC machining is getting smarter with new technology. AI helps write better programs and spots problems early. IoT connects machines to networks for live updates and fixes. Eco-friendly practices, like energy-saving machines and recyclable materials, are also growing. These changes make CNC machining faster and greener.