Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

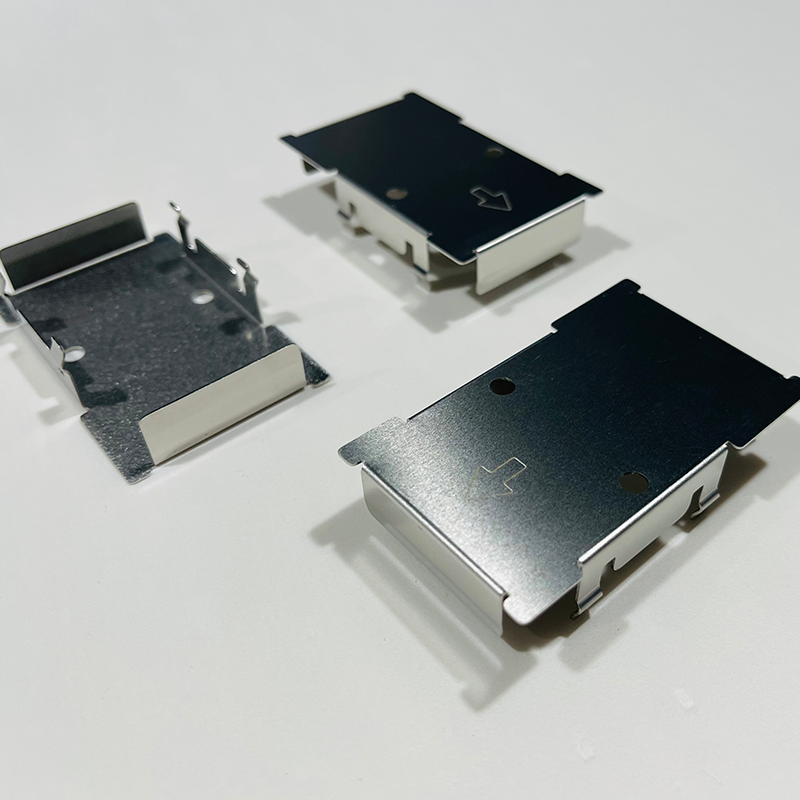

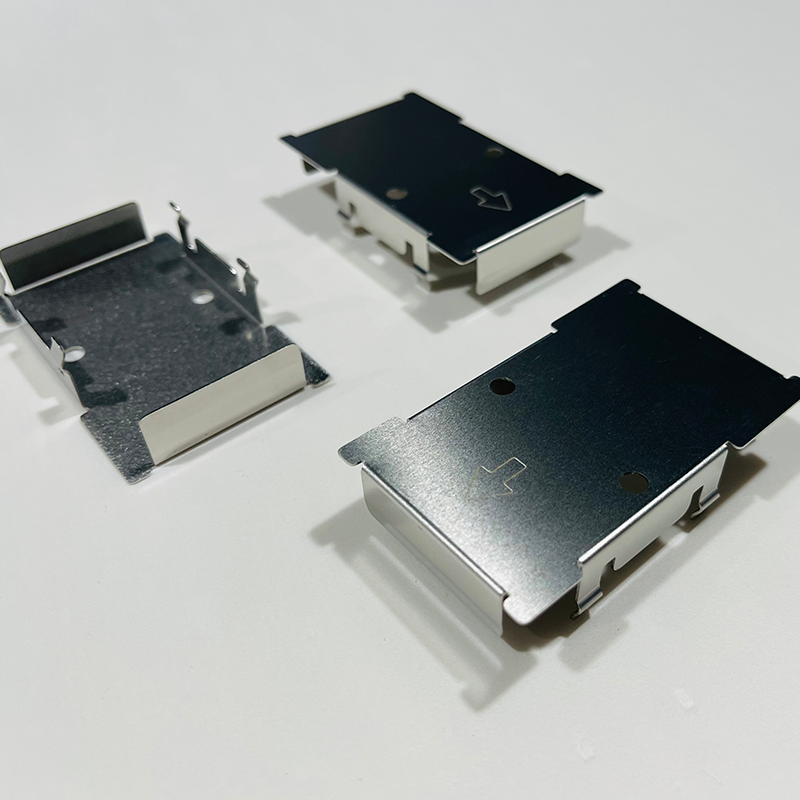

The Essential Guide to OEM Metal Bending Services

Metal bending is a fundamental process in modern manufacturing, playing a pivotal role in creating components for various industries. Whether it’s for automotive, aerospace, construction, or electronics, the precision and quality of bent metal parts can significantly impact the performance and durability of the final product. This is where OEM metal bending services come into play, offering tailored solutions to meet specific needs. In this blog, we'll explore what OEM metal bending services are, their benefits, applications, and why partnering with a reliable provider is crucial for your business.

What are OEM Metal Bending Services?

OEM stands for Original Equipment Manufacturer. OEM metal bending services involve the custom production of bent metal parts according to the specifications provided by the client. These services cater to businesses that require unique metal components for their products. By outsourcing this process to a specialized provider, companies can ensure they receive high-quality parts that meet their exact requirements without the need for in-house production.

Benefits of OEM Metal Bending Services

1. Precision and Quality: Professional OEM metal bending services use advanced machinery and technology to achieve high levels of precision. This ensures that every part produced meets the exact specifications, reducing the risk of errors and improving the overall quality of the final product.

2. Cost-Effective: Outsourcing metal bending to an OEM service provider can be more cost-effective than maintaining an in-house production facility. It eliminates the need for investing in expensive machinery, training staff, and maintaining equipment, allowing companies to focus on their core business operations.

3. Flexibility: OEM metal bending services offer great flexibility in terms of design and production volume. Whether you need a small batch of custom parts or large-scale production, these services can accommodate your needs, providing a scalable solution that grows with your business.

4. Expertise and Experience: OEM providers have specialized knowledge and experience in metal bending. They understand the intricacies of different materials and bending techniques, ensuring optimal results for each project. Their expertise can also help in identifying potential design improvements and cost-saving opportunities.

5. Time-Saving: By leveraging the expertise and resources of an OEM metal bending service, companies can reduce lead times and speed up their production processes. This is particularly beneficial in industries where time-to-market is critical.

Applications of OEM Metal Bending Services

OEM metal bending services are utilized in a wide range of industries and applications. Here are a few examples:

- Automotive: Bent metal parts are essential in the automotive industry for manufacturing frames, exhaust systems, and various other components. Precision bending ensures that these parts fit perfectly and function optimally.

- Aerospace: In aerospace, the quality and accuracy of metal parts are paramount. OEM metal bending services provide the necessary precision for components used in aircraft structures, landing gears, and more.

- Construction: The construction industry relies on metal bending for creating structural elements, such as beams, columns, and supports. These services ensure that metal components are strong and durable, meeting safety standards.

- Electronics: Bent metal parts are used in electronic enclosures, chassis, and other components. OEM services ensure that these parts meet the precise dimensions required for proper functioning.

Choosing the Right OEM Metal Bending Service Provider

When selecting an OEM metal bending service provider, it’s important to consider several factors to ensure you partner with a reliable and capable company.

1. Experience and Reputation: Look for a provider with a proven track record and positive reputation in the industry. An experienced provider will have the expertise to handle complex projects and deliver high-quality results.

2. Technology and Equipment: Ensure that the provider uses state-of-the-art machinery and technology. Advanced equipment can achieve higher precision and efficiency, leading to better quality parts.

3. Customization Capabilities: Choose a provider that offers a high degree of customization. They should be able to work with various materials and accommodate unique design specifications.

4. Quality Assurance: A reliable OEM metal bending service provider should have robust quality control processes in place. This includes regular inspections, testing, and adherence to industry standards to ensure the consistency and reliability of their products.

5. Customer Service: Excellent customer service is crucial for a successful partnership. The provider should be responsive, communicative, and willing to collaborate closely with you to meet your needs.

Conclusion

OEM metal bending services are a vital resource for businesses across multiple industries. They offer precision, cost-effectiveness, flexibility, and expertise that can enhance the quality and performance of your products. By choosing the right service provider, you can ensure that your metal components are manufactured to the highest standards, meeting your exact specifications and contributing to the success of your business.

Investing in OEM metal bending services can streamline your production process, reduce costs, and improve the overall quality of your products. As technology continues to advance, these services will only become more integral to modern manufacturing, providing innovative solutions to meet the evolving needs of various industries.

In conclusion, OEM metal bending services offer a comprehensive solution for businesses seeking high-quality, customized metal components. Whether you're in the automotive, aerospace, construction, or electronics industry, partnering with a reliable OEM provider can provide significant benefits, ensuring that your products are built to perform and last.