Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Research on CNC machining technology and application optimization measures for complex workpieces

Abstract: Complex workpieces are characterized by high technological complexity, uneven structure and other characteristics, which make machining more difficult. In order to ensure its processing quality, it is necessary to introduce CNC machining technology, with the help of technical advantages to improve the processing quality and efficiency of complex workpieces. Based on this, the article to CNC machining technology on the research object, first of all from the applicability, processing accuracy of the advantages of CNC machining technology, followed by the introduction of rounded corner feature recognition, chamfer feature recognition, hole feature recognition of the three complex workpiece CNC machining identification technology, and finally put forward the optimization of the application of CNC machining technology of complex workpieces, with a view to providing reference for the relevant practitioners.

In the context of the rapid development of the industrial manufacturing industry, the processing requirements of complex workpieces continue to improve. Traditional processing technology to manual processing, semi-automated processing mode, processing accuracy control effect is poor, can not meet the complex workpiece processing quality requirements. The higher degree of automation of CNC machining technology can not only improve the quality and efficiency of complex workpiece processing, but also save resources. Therefore, based on the actual situation of complex workpieces, the development of systematic CNC machining program, select the appropriate tool, continue to optimize the design of the tool path, so as to strengthen the effect of the application of CNC machining technology to improve the processing quality of complex workpieces.

1 Advantages of CNC machining technology

2 Complex workpiece CNC machining identification technology

Based on the processing characteristics of complex workpieces, before the application of CNC machining technology, it is necessary to identify the characteristics of complex workpieces, to distinguish them from other workpieces. At present, some complex workpiece CNC machining identification mainly rounded corner feature identification, chamfer feature identification and hole feature identification.

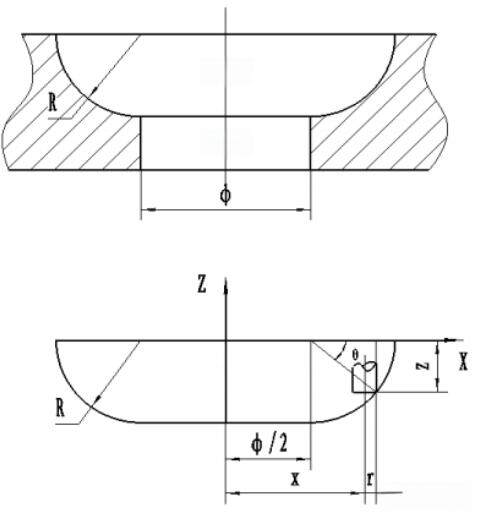

2.1 Fillet feature recognition

2.2 Chamfer feature recognition

Chamfer features are mainly divided into two types: plane chamfer and beveled chamfer. From the perspective of mechanical properties, chamfer features can reduce the stress concentration of complex workpieces and effectively improve their fatigue strength. The process of chamfer feature recognition is basically the same as that of fillet feature recognition, but the difference is that it is necessary to identify the chamfer feature individually, identify the surface that does not contain smooth edges, and calculate the aspect ratio of the surface, which is usually within 5. During the chamfer feature recognition, the angle between the chamfered feature face and the neighboring faces should be calculated, and the angle is usually controlled at 60° to 120°.

2.3 Hole feature recognition

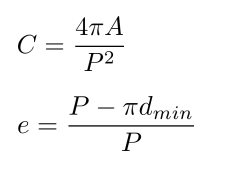

During the CNC machining of complex workpieces, hole feature recognition is very critical to further determine the shape, size, angle, etc. of the hole processing. Complex workpiece hole shape characteristics can be expressed using roundness, circularity, eccentricity. The formulas for roundness and circularity are respectively:

In the formula: C is the roundness; A is the area of the hole; P is the circumference of the hole; e is the roundness; dmin is the diameter of the hole internal tangent circle. Through the calculation to determine whether the complex workpiece has the shape characteristics of the hole.

3 Complex workpiece CNC machining technology application optimization measures

3.1 CNC Programming

CNC programming is the core link of complex workpiece CNC machining, including manual programming and automatic programming in two ways. Manual programming requires programmers to have a wealth of knowledge of CNC machining and high programming ability. While automatic programming is the use of computer-aided design and computer-aided manufacturing software, through the graphical interface and input parameters to automatically generate CNC programs. Specifically, according to the complex workpiece drawing pattern, it will be converted into data parameters, input CNC machine tool into instructions, through the CNC machine tool control program to issue instructions, prompting the tool to reach the specified position, and according to the set trajectory operation, so as to complete the complex workpiece CNC machining. After the end of CNC programming into the CNC machining program, the enterprise in order to ensure that programming to meet the requirements of quality and efficiency of complex workpiece processing, the need to organize operators, technicians, managers, the establishment of the spindle space plane and the workpiece space plane coordinate system, the scientific design of the two planes of the cutting tool position, and to do a good job of precision control.

3.2 Selection of suitable CNC machine tools

CNC machine tool is the control component of CNC machining technology, divided into hardware and software. Among them: hardware, including CNC devices, sensors, etc., through the cooperative work, control the machine movement and processing; software, including CNC programming software, CNC operating system, CNC simulation software, etc., through the computer and CNC devices for communication and data exchange, control and monitoring of the machine tool. To give full play to the advantages of CNC machining technology, it is necessary to continuously improve the performance and stability of the CNC system to ensure the function and reliability of the CNC machine tool hardware and software.

Due to the difficulty of complex workpiece processing, in order to ensure the quality and safety of workpiece processing, it is necessary to choose a higher precision CNC machine tool. At present, the complex workpiece CNC machine tools in some countries mainly include multi-axis linkage machine tools, three-axis linkage machine tools, single-axis linkage machine tools, according to the characteristics of complex workpieces to choose the appropriate CNC machine tools. In addition, the safety and reliability of CNC machine tools is also an important indicator to consider when choosing, improve the safety and reliability of CNC machine tools to avoid failure during subsequent processing. Failure will not only affect the quality of complex workpiece processing, but also affect the productivity of the workpiece. Operators need to actively carry out CNC machine debugging to ensure that its performance indicators at the normal level.

3.3 Optimize tool selection

The application of CNC machining technology will be affected by the impact of the tool. The higher the adaptability of the tool and the workpiece, the higher the processing quality and efficiency. Should be based on the complex workpiece material hardness, cutting performance and processing requirements, a reasonable choice of tool materials, geometric parameters and sharpening methods, in order to improve cutting efficiency and extend tool life. The processing requirements of complex workpiece will also affect the tool selection. For example, for materials with high hardness, the staff can choose a larger feed rate and smaller depth of cut to reduce the cutting force and cutting temperature.

As the complex workpiece is irregular shape, its cutting operation is more frequent, resulting in a long time in the running state of the tool, in order to avoid tool damage during CNC machining, need to prioritize the selection of high rigidity tool. Cutting tools during cutting will produce wear, once the wear control is not appropriate, the degree of wear exceeds the standard of the tool applied to the CNC machining of complex workpieces, will directly affect the quality of the workpiece processing. Therefore, during CNC machining, technicians need to carry out regular tool wear inspection, when the degree of wear is 15% to 20%, the need for timely replacement of tools. Cutting volume is a key parameter in the CNC machining process of complex workpieces, and good cutting volume control has the effect of reducing tool wear and balancing the machining speed. The formula for calculating the cutting volume is:

![]()

In the formula: A is the productivity; Vc is the processing cutting speed; f is the cutting feed; p is the cutting depth. Based on the actual situation of complex workpiece processing, balancing the cutting elements, controlling the depth of cut and speed of workpiece processing, slowing down the speed of tool wear, and effectively improving the efficiency of CNC machining of complex workpieces.

3.4 Workpiece clamping

Workpiece clamping has a greater impact on the effect of CNC machining of complex workpieces. Incorrect selection of the clamping method will directly lead to workpiece processing quality problems. Therefore, during the actual processing, operators need to raise the importance of workpiece clamping, based on the actual situation of complex workpieces, optimize the workpiece clamping method. Operators need to consider a number of factors, design the friction between the complex workpiece and the fixture, contact position and tightness, to ensure that the processing effect, improve processing quality and efficiency. At the same time, in order to avoid the risk of CNC machining of complex workpieces caused by errors in workpiece clamping parameters, operators need to actively carry out parameter checking to ensure that the adjusted clamping meets the processing requirements of complex workpieces.

3.5 Tool path generation

In the complex workpiece CNC machining, tool path generation is critical, only to ensure that the tool path is accurate, CNC machine tools can be programmed to correctly perform machining operations to ensure the processing quality of complex workpieces. There are differences in the CNC machining path of different workpieces, and it is necessary to optimize the tool route in combination with the actual situation. At present, there are three main modes of CNC machining technology tool path generation. First, the processing of large-volume complex workpieces is mainly used to specify the programming method, taking into account the factors affecting CNC machining, and continuously optimizing the tool path design. Second, with the help of generating program segments to complete the tool path design. Third, the data structure to complete the CNC programming.

In the process of CNC machining of complex workpieces, the operator needs to focus on the tool path design, based on the requirements of the workpiece CNC machining of the amount of cutting, select the appropriate type of tool, control the cutting angle and other parameters, continue to optimize the tool trajectory, to avoid the occurrence of tool collision, to ensure the safety of machining production.

4 Conclusion

In the context of the intelligent development of machinery manufacturing, the status of CNC machining technology continues to improve, effectively improving the quality and efficiency of machining products, effectively promoting the development of the field of mechanical production. In order to improve the effect of the application of CNC machining technology, continue to improve the quality of complex workpiece processing, manufacturing enterprises need to increase the research efforts of CNC machining technology, design CNC programming based on the actual situation of complex workpieces, select the appropriate machine tools and cutting tools, improve the effect of chip volume control, optimize the design of tool paths, and give full play to the advantages of CNC machining technology.