Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How to identify the ideal laser cutting service for your metal projects?

Choosing a laser metal cutting service is essential to the success of any project involving laser-cut metal. Accurate laser metal cutting guarantees impeccable results, even for the most complex designs. Conversely, the wrong choice can lead to additional costs, significant delays and unsatisfactory final quality. Metal laser cutting stands out for its exceptional precision and its ability to work on a variety of materials such as steel, stainless steel or aluminum. Identifying the ideal service for metal laser cutting optimizes resources and ensures fast, efficient execution.

Key points

- Choose a laser cutting service that offers the power and precision you need to guarantee impeccable results.

- Check the service's compatibility with the different types of metal you wish to use, such as steel, stainless steel or aluminum.

- Make sure the service provider uses modern technology and advanced software to optimize the quality and customization of your cuts.

- Prioritize safety and equipment maintenance to guarantee a safe working environment and reliable results.

- Seek price transparency and compare quotes to maximize the value of your investment without compromising quality.

- Work closely with the supplier, clearly defining your requirements and maintaining regular communication throughout the project.

- Test prototypes before final production to validate cut quality and avoid costly mistakes.

Essential criteria for choosing a metal laser cutting service

Laser cutting power and precision

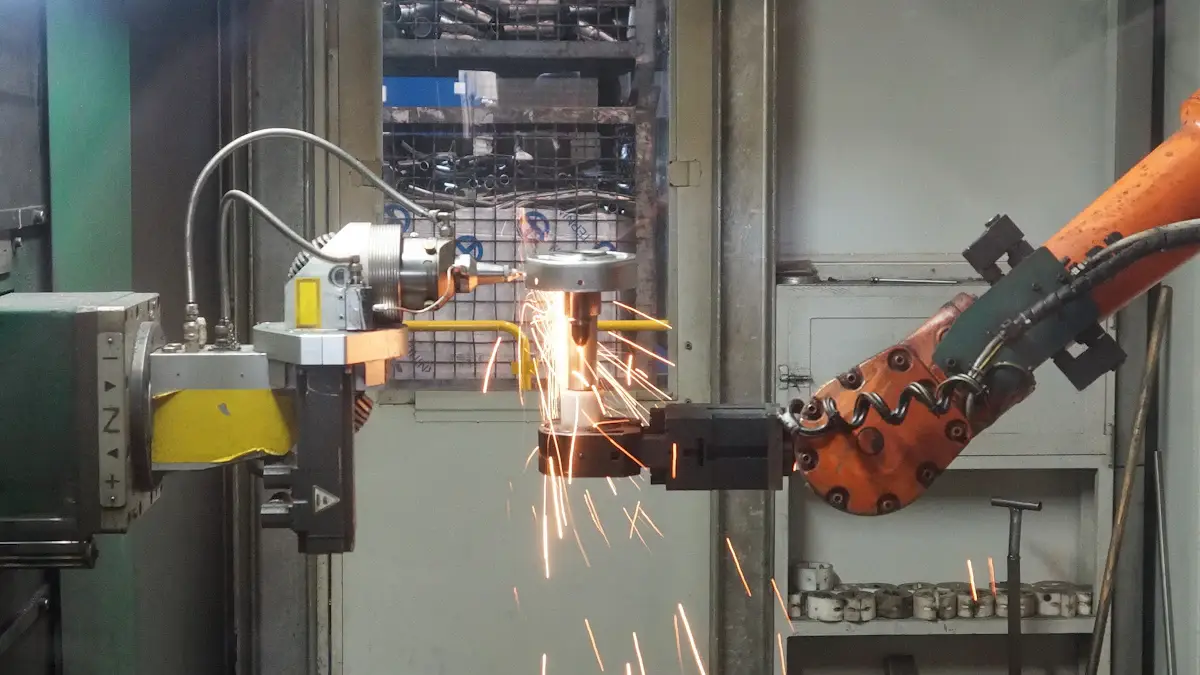

Laser power plays a fundamental role in the quality and speed of cutting. Laser cutting machines are available in a wide range of power ratings, from models suitable for engraving to industrial equipment capable of processing thick metals. High power enables fast, efficient cutting of a wide range of metallic materials, while maintaining outstanding precision. Fiber laser cutting machines, for example, are distinguished by their high power density, ideal for projects requiring fast, clean cutting.

Precision, meanwhile, guarantees impeccable results, even for complex designs. Precise cutting reduces errors and minimizes material waste. Quality metal laser cutting services use modern equipment to achieve optimum precision, essential for demanding projects.

Compatibility with metal materials

A good laser cutting service must be able to work with different types of metal. The most commonly used materials include steel, stainless steel, aluminum, brass and copper. Each metal has specific properties, such as density or thermal conductivity, which influence the cutting method. For example, stainless steel requires the right laser power to avoid burrs, while lighter aluminum requires a different approach.

Compatibility with these materials ensures that the service can meet your specific needs. Before choosing a service provider, it's essential to check that they have the equipment needed to process the metal in your project efficiently.

Software and technologies used for cutting

Software and technology play a key role in the quality and customization of cuttings. Modern services use advanced software to precisely design and program cut-outs. These tools make it possible to create complex designs and customize dimensions to customer specifications.

Technologies such as fiber laser cutting machines offer increased efficiency thanks to their speed and adaptability. This modern equipment guarantees high-quality finishes, without burrs or slag. What's more, some suppliers offer online configurators, enabling customers to customize their projects before production.

“Advanced technology and high-performance software are major assets in guaranteeing accurate results that meet expectations.”

When choosing a metal laser cutting service, it's crucial to ensure that the provider uses state-of-the-art equipment and software. This guarantees not only superior quality, but also greater efficiency in project execution.

Equipment safety and maintenance

The safety of laser cutting equipment is a key criterion when choosing a service provider. Laser cutting machines, especially industrial models, operate at high power levels, which can present risks if not used correctly. A reliable provider must adhere to strict safety standards to protect operators and guarantee a safe working environment. This includes the use of protective devices, such as safety screens, and the training of technicians in the use of equipment.

Regular maintenance of laser cutting machines also plays a key role in the quality of cuts and the durability of equipment. Modern machines, such as fiber laser cutters, require precise maintenance to maintain their efficiency and avoid breakdowns. A reliable service provider must have a rigorous maintenance program in place, including lens cleaning, checking optical systems and verifying mechanical components. These practices guarantee optimum performance and reduce the risk of project downtime.

“Well-maintained, safe equipment reflects a provider's professionalism and ensures reliable results for customers.”

Cost and price transparency

The cost of a metal laser cutting service varies according to several factors, such as the complexity of the project, the type of metal used and the thickness of the materials. However, transparency of pricing remains an essential element in establishing a relationship of trust with the service provider. A good supplier should provide clear, detailed quotes, including all associated costs, such as cutting, finishing and any post-cutting treatments.

Comparing prices between different providers can help identify a competitive offer without compromising quality. Services using advanced technologies, such as fiber laser cutting machines, can justify slightly higher rates thanks to their precision and speed. However, it's important not to focus on price alone. Too low a price could indicate a lack of quality or obsolete equipment.

To maximize the value of the investment, it is advisable to choose a service provider who offers solutions tailored to the specific needs of the project, while maintaining total transparency on costs.

The advantages of a laser cutting service for your metal projects

Unrivalled precision for complex designs

Laser cutting offers exceptional precision, essential for projects requiring complex designs. Modern machines can produce clean, detailed cuts, even on small parts. This precision guarantees results in line with specifications, reducing errors and post-production adjustments. Companies using metal laser cutting can produce parts with perfect contours, meeting the requirements of sectors such as aeronautics, automotive and decoration.

Advanced technologies, such as fiber lasers, ensure uniform cutting across the entire metal surface. This makes it possible to create complex patterns without compromising quality. This unrivalled precision is a major asset for projects requiring an impeccable finish.

Fast turnaround for short deadlines

Laser cutting is distinguished by its speed of execution. Metal laser cutting machines operate at high speeds, considerably reducing production lead times. This speed enables companies to meet tight deadlines while maintaining optimum quality. Unlike traditional methods, laser cutting does not require frequent tool changes, further speeding up the process.

Service providers equipped with modern machines can process several orders in a short space of time. This is particularly advantageous for series projects or urgent orders. By choosing a laser cutting service, companies benefit from a fast, efficient solution to their needs.

Versatility for various types of metal (steel, stainless steel, aluminum, etc.)

Metal laser cutting offers great versatility, making it possible to work on a variety of metal materials. Modern machines can easily adapt to metals such as steel, stainless steel, aluminum, brass and copper. Each metal has its own specific properties, but laser technology guarantees optimum results for each of them.

For example, stainless steel, often used in the food or medical industries, requires precise cutting to avoid burrs. Lighter aluminum requires a different approach, but is perfectly compatible with laser cutting. This versatility enables companies to carry out a wide range of projects without having to change suppliers.

“The ability to work on different metals makes laser cutting an essential solution for metal projects.”

By opting for a laser cutting service, companies can meet diversified needs while maintaining consistent quality. This flexibility is a key advantage for projects requiring a variety of materials.

A cost-effective solution thanks to improved efficiency

Laser cutting stands out for its remarkable efficiency, making it a cost-effective solution for many metal projects. Modern machines, equipped with advanced technologies, optimize every stage of the process. They reduce material waste thanks to greater precision, thus minimizing waste. This optimization enables companies to maximize the use of available resources.

Production costs are also reduced thanks to the speed of execution of laser cutting machines. Unlike traditional methods, this equipment does not require frequent tool changes or lengthy set-ups. This reduces downtime and speeds up project delivery. As a result, companies can meet tight deadlines while maintaining consistent quality.

Another economic advantage lies in the versatility of laser cutting machines. They can be adapted to different types of metal without the need for additional equipment. This flexibility eliminates the need to invest in several machines to process different materials. Companies benefit from a single solution to meet a variety of needs.

“Investing in a modern laser cutting service guarantees better cost management and increased efficiency for every project.”

By choosing a competent service provider, companies can also benefit from personalized advice to optimize their projects. These recommendations help reduce unnecessary expenditure and improve end results. A well-planned approach, combined with machine efficiency, ensures maximum profitability for every investment.

How to evaluate a metal laser cutting service provider

Experience and skills in laser cutting

A service provider's experience in the field of laser metal cutting is an essential criterion for guaranteeing quality results. An experienced company masters the specifics of different metal materials, such as stainless steel, aluminum or copper. It knows how to adapt cutting parameters to the properties of each metal, such as density or thermal conductivity. For example, the high conductivity of copper requires special expertise to avoid cutting defects.

Technicians' skills also play a crucial role. Skilled operators ensure optimum use of laser cutting machines, reducing errors and material waste. A competent team can also offer solutions tailored to specific customer requirements, whether for complex projects or large production runs.

“An experienced and competent service provider guarantees accurate results that meet expectations, even for the most demanding projects.”

Customer reviews and recommendations

Customer reviews provide valuable insight into the quality of a supplier's services. Testimonials often highlight important aspects, such as the precision of cuts, adherence to deadlines or the quality of customer service. A company with positive feedback inspires confidence and reflects a high level of satisfaction.

Recommendations from loyal customers or partner companies also reinforce a service provider's credibility. This feedback enables us to assess the company's ability to meet expectations in a variety of contexts. For example, a service provider recommended by players in the automotive or aerospace industries demonstrates expertise in demanding sectors.

For a complete picture, it's advisable to consult several sources, such as online review platforms, social networks or case studies published by the company. This information helps you to make an informed decision.

Modern technology and equipment

The technologies used by a provider directly influence the quality and efficiency of the cuts. Modern laser cutting machines, such as fiber lasers, offer unrivalled precision and remarkable speed. This equipment can produce clean cuts, even on thick metals or complex designs. For example, fiber lasers guarantee uniform cutting on materials such as mild steel or aluminum.

Advanced software also plays a key role. They can be used to design customized cut-outs and optimize the use of materials. Some providers even offer online configurators, making it easier for customers to customize projects.

“Modern equipment and advanced technologies ensure high-quality results and greater efficiency in project execution.”

A provider that invests in cutting-edge technology demonstrates its commitment to innovation and customer satisfaction. This guarantees not only optimum performance, but also adaptation to market developments.

Quality of customer service and support

Quality customer service plays a crucial role in the choice of a metal laser cutting provider. Companies that focus on support offer a smooth, reassuring customer experience. This starts with clear, responsive communication. Customers need to be able to ask questions, obtain detailed information and receive prompt answers to their concerns.

A good service provider supports its customers at every stage of the project. This includes analyzing requirements, selecting suitable materials and customizing cut-outs. For example, for metals such as stainless steel or aluminum, technical support ensures optimum results. Companies that offer advice on technical specifications, such as thickness or finishes, help their customers avoid costly mistakes.

“Personalized support ensures better understanding of expectations and execution in line with requirements.”

Modern laser cutting services often incorporate digital tools to enhance the customer experience. Some providers offer online configurators, enabling users to visualize their projects before production. These tools enhance transparency and facilitate decision-making.

Another essential aspect is deadline management. Reliable companies respect deadlines and inform their customers of any changes. This transparency builds trust and avoids the frustration of unexpected delays.

Finally, quality customer service is distinguished by its after-sales follow-up. Serious service providers ensure that customers are satisfied with the results, and offer solutions in the event of problems. This level of commitment reflects professionalism and a desire to build lasting relationships with their customers.

In short, exemplary customer service rests on three main pillars:

- Clear, responsive communication to meet customer needs.

- Personalized technical support to guarantee compliant results.

- Attentive after-sales follow-up to ensure total satisfaction.

Choosing a service provider who values these aspects means you can carry out your laser cutting projects with peace of mind and efficiency.

Tips for maximizing the results of your laser cutting projects

Clearly define your needs and specifications

The success of a laser cutting project hinges on a precise definition of requirements. Companies need to identify the dimensions, shapes and materials required before contacting a supplier. A clear specification avoids misunderstandings and ensures that the supplier fully understands expectations.

For example, if a project requires complex cut-outs in stainless steel, it is essential to specify the thickness of the metal and the desired finishes.

Customers must also provide detailed technical drawings or digital models. These documents make it easier to program the machines and ensure that the cut complies with requirements. Careful preparation reduces errors and optimizes the use of materials, thus minimizing waste.

Close collaboration with the supplier

Close collaboration with the supplier greatly improves results. Companies should maintain regular communication throughout the project. This approach enables any problems to be resolved quickly, and specifications adjusted if necessary.

Experienced suppliers often offer valuable advice on materials and cutting techniques. They can recommend adjustments to improve quality or reduce costs. For example, a provider may suggest a specific cutting method to maximize precision on delicate metals such as copper.

“Proactive collaboration with the service provider ensures a better understanding of expectations and flawless execution.”

Companies also need to ensure that the supplier meets agreed deadlines. Effective time management builds trust and helps keep projects on schedule.

Testing prototypes before final production

Prototype testing is a crucial step in guaranteeing the quality of results. Companies should ask their supplier to produce a sample before launching mass production. This prototype is used to check the precision of cuts, the quality of finishes and compliance with specifications.

A well-made prototype can reveal necessary adjustments, such as design modifications or improvements in the choice of materials.

This step reduces the risk of costly errors during final production. It also provides an opportunity to test the durability and functionality of the cut parts. Companies can thus ensure that the final product will meet expectations.

In short, maximizing the results of a laser cutting project requires rigorous preparation, active collaboration and prior validation with prototypes. These practices guarantee results that are precise, efficient and in line with specific requirements.

Common mistakes to avoid when choosing a laser cutting service

Neglecting material compatibility

Each metal has specific properties that influence the cutting method. For example, stainless steel requires the right laser power to avoid burrs, while lighter aluminum requires a different approach. Ignoring these particularities can lead to unsatisfactory results, such as inaccurate cuts or poor-quality finishes.

The manufacturers questioned in a recent survey stressed the importance of material compatibility in their projects. A majority expressed a strong interest in laser cutting, but some mentioned constraints linked to inappropriate material choices. This shows that compatibility remains a key factor in ensuring project success.

To avoid this mistake, it's essential to check that the supplier has the necessary equipment to handle the specific metal for your project. Clear communication on requirements and technical specifications ensures that the chosen service will meet expectations.

Choosing on price alone

Cost plays an important role in decision-making, but focusing on price alone can be risky. Low-cost laser cutting services often use obsolete equipment or lack rigor in their processes. This can lead to delays, errors or inferior results.

A reliable service provider justifies its prices by using modern technologies, such as fiber laser cutting machines, and by providing high-quality customer service. These investments guarantee precise cuts and on-time delivery. Companies therefore need to assess value for money rather than just initial cost.

“An attractive tariff should never compromise the quality or reliability of the service.”

Comparing several detailed quotes, including costs for cutting, finishing and post-cut processing, helps identify a competitive offer without sacrificing quality.

Don't check service provider's reviews or experience

A supplier's experience and reputation directly reflect the quality of their services. Ignoring these aspects can lead to disappointing collaborations. Experienced companies master the specifics of materials and technologies, enabling them to respond effectively to customer needs.

Customer reviews offer valuable insight into a supplier's reliability. Testimonials often highlight essential elements, such as precision cutting or adherence to deadlines. For example, positive recommendations from manufacturers or industrial subcontractors reinforce a supplier's credibility.

To avoid this mistake, it is advisable to consult several sources, such as online review platforms or case studies published by the company. Thorough research ensures an informed decision and reduces the risk of dissatisfaction.

In conclusion, choosing a metal laser cutting service requires careful attention to essential criteria such as power, precision and material compatibility. Advantages such as speed and versatility reinforce interest in this technology. Evaluating providers on their experience, modern equipment, and customer service guarantees optimal results.

“An informed decision is based on a rigorous analysis of specific needs and available offers.”

Don't hesitate to contact a qualified service provider to transform your ideas into precise, efficient metalwork.