Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

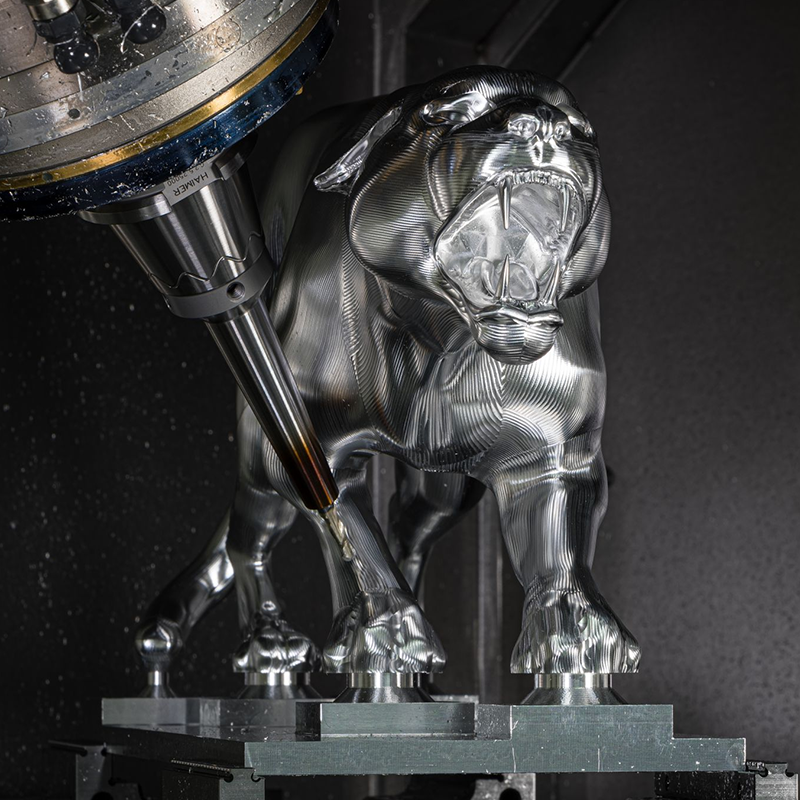

China CNC Precision Machining Service Wholesale: The Ultimate Guide

In today's fast-paced manufacturing world, precision and efficiency are crucial. Among the most sought-after services is CNC precision machining. With advancements in technology and the growing demand for high-quality parts, many businesses are turning to China CNC precision machining service wholesale providers. This guide delves into the intricacies of CNC precision machining, why China is a leading provider, and how to choose the right wholesale partner.

What is CNC Precision Machining?

Understanding CNC

CNC stands for Computer Numerical Control. It's a process where pre-programmed computer software dictates the movement of factory tools and machinery. This method is used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

The Precision Advantage

Precision machining involves removing material from a workpiece while maintaining extremely tight tolerances. It’s pivotal in producing intricate and complex parts that must meet strict specifications. CNC precision machining achieves this through high accuracy and repeatability, making it indispensable for industries such as aerospace, medical, and automotive.

Why Choose China CNC Precision Machining Service Wholesale?

Cost Efficiency

One of the primary reasons businesses opt is the cost advantage. China offers competitive pricing due to lower labor costs and economies of scale. This cost efficiency allows businesses to procure high-quality components without breaking the bank.

Advanced Technology

China has heavily invested in advanced CNC machinery and technology. Many Chinese CNC precision machining service wholesale providers use state-of-the-art equipment, ensuring that they can meet the stringent requirements of various industries.

Skilled Workforce

Chinese manufacturers boast a skilled workforce adept in CNC precision machining. Continuous training and a strong emphasis on technical education ensure that workers are well-versed in the latest machining techniques and quality standards.

Comprehensive Services

The China's wholesale providers offer a wide range of services, including milling, turning, drilling, and grinding. This comprehensive suite of services allows businesses to source all their machining needs from a single provider, simplifying the supply chain and enhancing efficiency.

Key Considerations When Choosing a China CNC Precision Machining Service Wholesale Provider

Quality Assurance

Quality is paramount when it comes to precision machining. Ensure that the provider has robust quality control measures in place. This includes certifications such as ISO 9001 and regular quality audits. A reputable wholesale provider will have a documented quality management system.

Production Capacity

Evaluate the production capacity of the provider to ensure they can meet your volume requirements. Whether you need small batch production or high-volume runs, the provider should have the flexibility to scale production as needed.

Lead Time

Timely delivery is crucial in manufacturing. Discuss lead times with potential providers and ensure they have a track record of meeting deadlines. A reliable wholesale provider will offer realistic lead times and adhere to them.

Technical Support

Effective communication and technical support are vital. Choose a provider that offers excellent customer service and technical support to address any issues promptly. This includes assistance with design modifications and troubleshooting during production.

Customization Capabilities

Your business may require customized parts that meet specific requirements. Ensure that the China's wholesale provider has the capability to handle custom projects. This includes the ability to work with various materials and complex designs.

Common Applications of CNC Precision Machining

Aerospace

The aerospace industry relies heavily on CNC precision machining for components that require high tolerances and superior material properties. Parts such as engine components, landing gear, and structural elements are often produced using CNC machining.

Medical Devices

Medical devices demand precision and reliability. CNC precision machining is used to manufacture surgical instruments, implants, and other medical devices that must meet strict regulatory standards.

Automotive

In the automotive industry, CNC precision machining is used to produce engine parts, transmission components, and other critical parts. The ability to maintain tight tolerances ensures that these parts perform reliably under extreme conditions.

Electronics

The electronics industry uses CNC machining to produce components for devices

such as smartphones, computers, and other consumer electronics. Precision is essential to ensure the functionality and reliability of these parts.

Industrial Equipment

CNC precision machining is used to manufacture parts for industrial machinery and equipment. This includes gears, bearings, and other components that must withstand heavy use and harsh environments.

Advantages of Partnering with a China CNC Precision Machining Service Wholesale Provider

Cost Savings

By partnering with a China's wholesale provider, businesses can achieve significant cost savings. Lower production costs translate to better profit margins and the ability to offer competitive pricing to customers.

Access to Advanced Technology

Chinese providers often have access to the latest CNC machining technology, which can result in higher quality and more efficient production processes. This technological edge can be a significant advantage in industries that demand high precision and innovation.

Flexible Production Capabilities

A good China's wholesale provider offers flexible production capabilities, allowing businesses to quickly adapt to changing demands. Whether it's a new product launch or an increase in production volume, these providers can scale their operations accordingly.

Streamlined Supply Chain

Sourcing from a China 's wholesale provider can streamline your supply chain. By consolidating your machining needs with a single provider, you can reduce lead times, simplify logistics, and improve overall efficiency.

Focus on Core Competencies

Outsourcing CNC precision machining to a reliable provider allows businesses to focus on their core competencies. This can lead to improved product development, marketing, and customer service, ultimately enhancing the overall competitiveness of the business.

Challenges and How to Overcome Them

Quality Control

Maintaining consistent quality can be a challenge when working with international providers. To overcome this, establish clear quality standards and conduct regular inspections. Partner with a China CNC precision machining service wholesale provider that has a strong reputation for quality and reliability.

Communication Barriers

Language and cultural differences can lead to communication barriers. To mitigate this, work with providers who have bilingual staff and experience in dealing with international clients. Clear and frequent communication is key to successful collaboration.

Logistics and Lead Times

Managing logistics and lead times can be complex when dealing with overseas providers. Plan ahead and establish clear timelines. Use reliable shipping partners and consider buffer times for unexpected delays.

Intellectual Property Protection

Protecting intellectual property (IP) is crucial when outsourcing manufacturing. Choose a China's wholesale provider with a strong track record of IP protection. Use non-disclosure agreements and consider legal counsel to safeguard your designs and innovations.

How to Find the Right China CNC Precision Machining Service Wholesale Provider

Research and Referrals

Start by conducting thorough research and seeking referrals from industry peers. Online reviews, industry forums, and trade shows can provide valuable insights into the reputation and capabilities of potential providers.

Evaluate Capabilities

Assess the technical capabilities of potential providers. This includes their machinery, software, and expertise in handling various materials and complex designs. A site visit or virtual tour can provide a firsthand look at their operations.

Request Quotes and Samples

Obtain quotes from multiple providers and compare pricing, lead times, and services offered. Request samples to evaluate the quality of their work. This will give you a clear idea of what to expect from the provider.

Check References

Ask for references from past clients and follow up with them to get feedback on their experiences. This can provide valuable insights into the provider's reliability, quality, and customer service.

Establish a Long-Term Partnership

Once you have chosen a China CNC precision machining service wholesale provider, aim to establish a long-term partnership. Building a strong relationship can lead to better collaboration, improved quality, and more favorable terms over time.

Conclusion

Choosing a China's wholesale provider can offer numerous advantages, from cost savings to access to advanced technology. By understanding the key factors to consider and the challenges involved, businesses can make informed decisions and find the right partner to meet their precision machining needs. With the right provider, companies can enhance their production capabilities, improve quality, and maintain a competitive edge in their respective industries.