Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

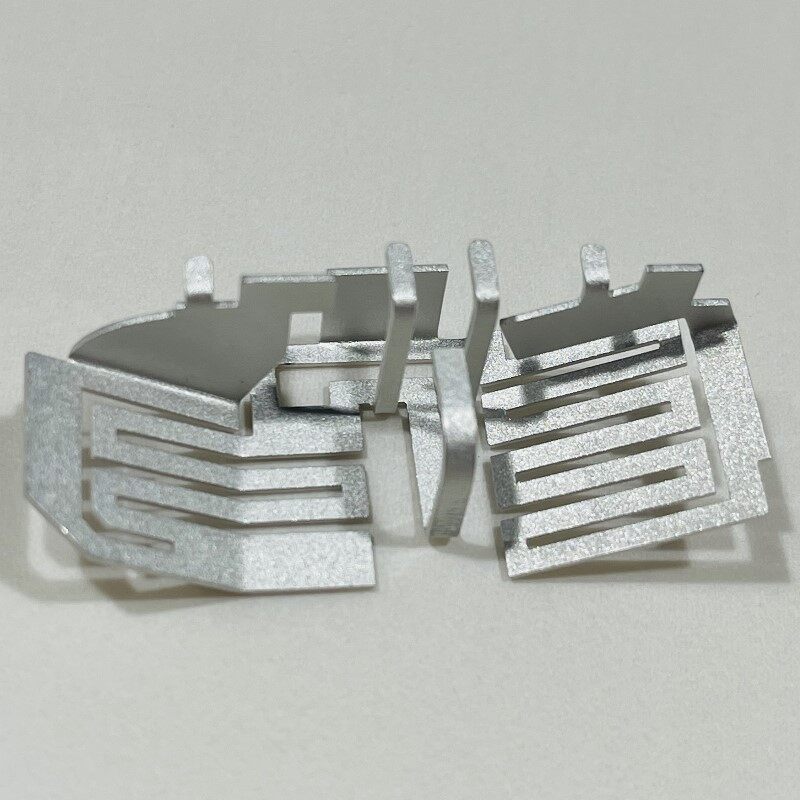

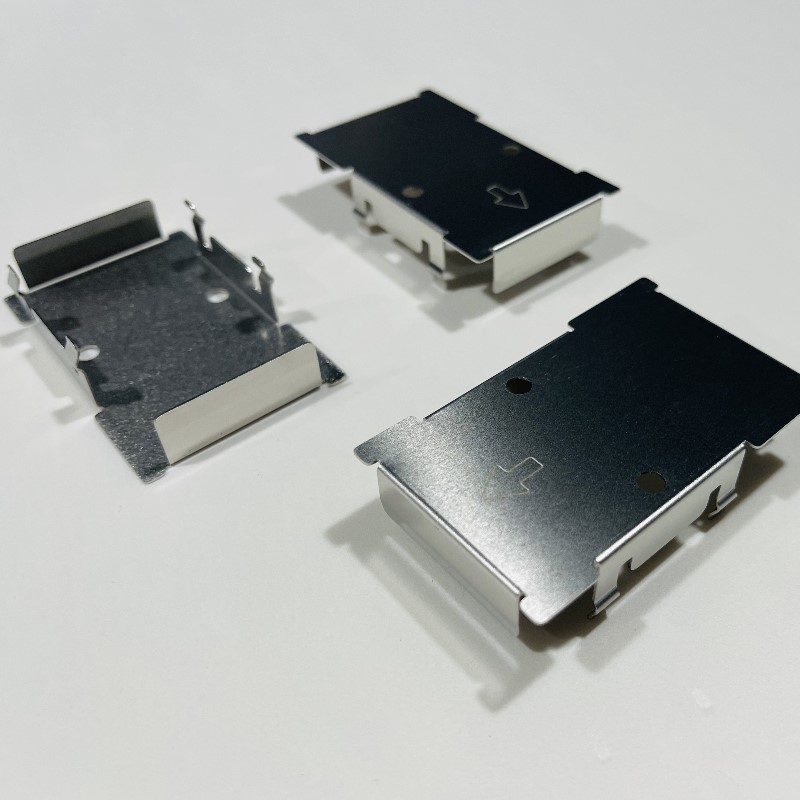

Sheet Metal Fabrication Services

Our rapid sheet metal prototyping and production services include a variety of tooled and manual manufacturing techniques and processes enabling us to realise some highly complex parts without expensive and time-consuming production tooling.

With our expertise in sheet metal fabrication, we can assist you in swiftly and accurately creating a variety of components, including enclosures, brackets, assemblies, weldments, cabinets, housings, and other sheet metal parts and prototypes. Our team is equipped with advanced tools and machinery to handle various sheet metal materials, such as steel, aluminum, and stainless steel.

Fast & Affordable Sheet Metal Prototypes

Future Parts can provide custom high-precision sheet metal prototypes and parts with wide range of processes:

Laser Cutting Service |

Plasma Cutting service |

Metal Bending service |

|

|

|

|

The Advantage of product

Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling. Its per-unit pricing lowers significantly in production volumes. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

Advantages of Sheet Metal Prototyping

- Quick and inexpensive

- High strength and durability

- Very efficient

- High Precision

- Sustainable solution

The Application of product

- Sheet Metal Fabrication is Used For

Rapid prototypes, low volume production, medical and communications products, housings and enclosures, everything from cars and space rockets and planes to air conditioners and soda cans.

- The Production Process of product

There are 3 common stages in the sheet metal fabrication process, all of which can be completed with various types of fabrication tools.

The stages are:

- Material removal

- Material deformation (forming)

- Assembling

The Feature of product

| Material | Picture | Description | Material Reference | Appearance |

| Copper |  |

Copper is an excellent material for sheet metal

fabrication. It is malleable, ductile, and an

extremely good conductor of both heat and

electricity. It is commonly used for electrical

equipment such as wiring and motors.

|

Red Copper, Brass | Pinkish Orage, Reddish Brown, Redish-Gold |

| Aluminium |  |

Aluminium sheet metal offers excellent strength

to weight ratio and corrosion resistance, making it

a popular choice in the aerospace and aviation,

automotive, and consumer electronics industry

|

AL5052, AL6061, 5052-H32 | Silvery White |

| Spring Steel |  |

Spring steel sheet has a low-alloy manganese,

medium-carbon steel or high-carbon steel with a

very high yield strength. It is a flexible material

commonly used to manufacture products,

including landing gears, saw blades, springs and

more.

|

Spring Steel | Gray Blue |

| Low Carbon Steel |  |

Though low carbon steel is weaker and softer, it

is good for situations that require structural steel

fabrication, such as automobile body components

and cans, as it has a very consistent yield strength

and is easy to shape.

|

||

| Cold Rolled Steel(CRS) |

|

At Future Parts, we can fabricate cold rolled steel

sheets. CRS is essentially hot rolled steel that has

been further strengthened by being allowed to

cool at room temperature and annealed. It

produces steel with closer dimensional tolerances

and a wider range of surface finishes than hot

rolling.

|

SPCC | Smooth Gray |

| Stainless Steel |  |

Stainless steel sheet cut to size is strong and

highly resistant to corrosion and rust, making it

ideal for parts that are exposed to different

elements for long periods and do not easily break.

|

SS304, SS301, SS316 | Silver |

| Steel |  |

At Future Parts, we can fabricate numerous grades of steel. While working on a low budget, mild carbon steel proves to be the best.

|

Mild Steel 45, AlSl 1020 (20#steel), SECC (Electro-galvanized steel), 45 Steel, 1018, Q235, Q345, Galvanized Steel | Silver |