Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

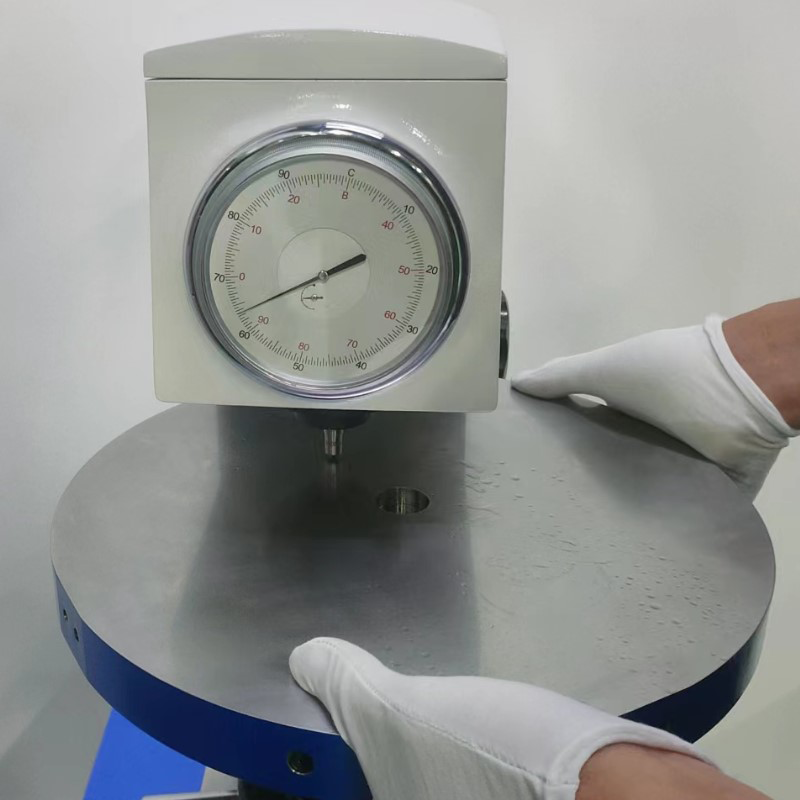

Quality inspection

Introducing our revolutionary Quality Inspection solution, designed to streamline and enhance your quality control processes.In today’s competitive market, ensuring the highest level of product quality is crucial for maintaining customer satisfaction and brand reputation. Our Quality Inspection system is a comprehensive tool that empowers businesses to effectively monitor and manage the quality of their products throughout the entire production cycle.

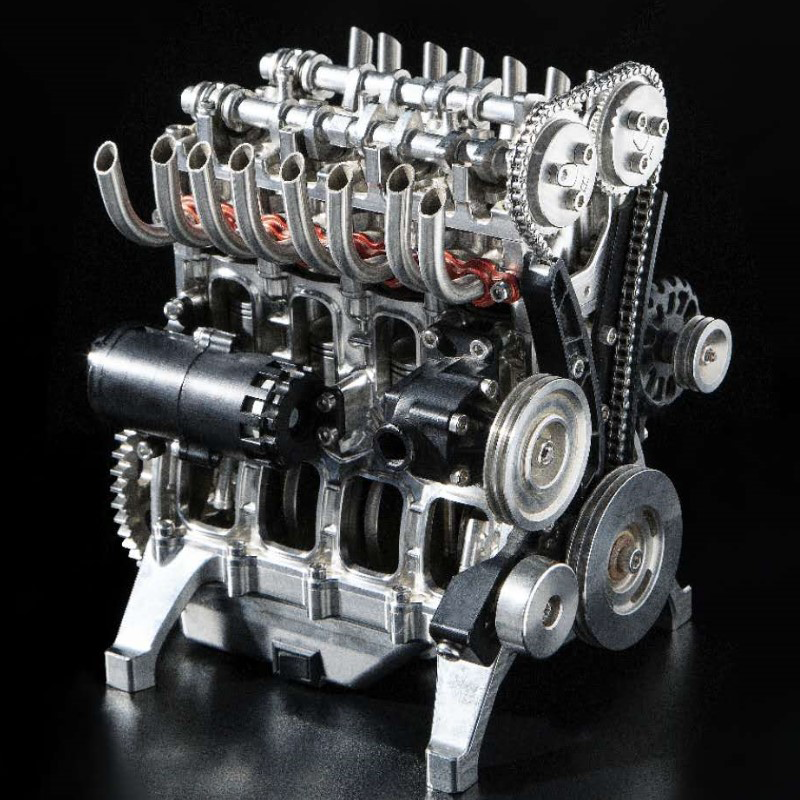

Quality Assurance for the Production of High-Quality Parts

Future Parts’s advanced manufacturing process, rigorous quality assurance measures, and adherence to industry standards ensure high quality, precision, and durability of your parts and prototypes.

ISO 9001:2015 certified

200,000 + quality parts produced

Tolerances down to ±0.0004″ (0.01mm)

How Future Parts Guarantees Superior Quality

- Well-Vetted Suppliers

We take great care in the selection process of our suppliers. We understand the critical role they play in our operations, and therefore, we dedicate significant effort to ensure that we collaborate with the best partners in the industry.

- Quality Materials

We place a strong emphasis on the quality of materials we use. Each batch of materials that arrives undergoes a meticulous testing process, allowing us to distinguish top-grade materials from those of inferior quality.

- Professional Project Engineer

Our team of professional project engineers who are dedicated to reviewing and refining your project ideas. They possess the knowledge and expertise to assess the feasibility of your designs and determine the most effective approach for creating the final prototype and production parts.

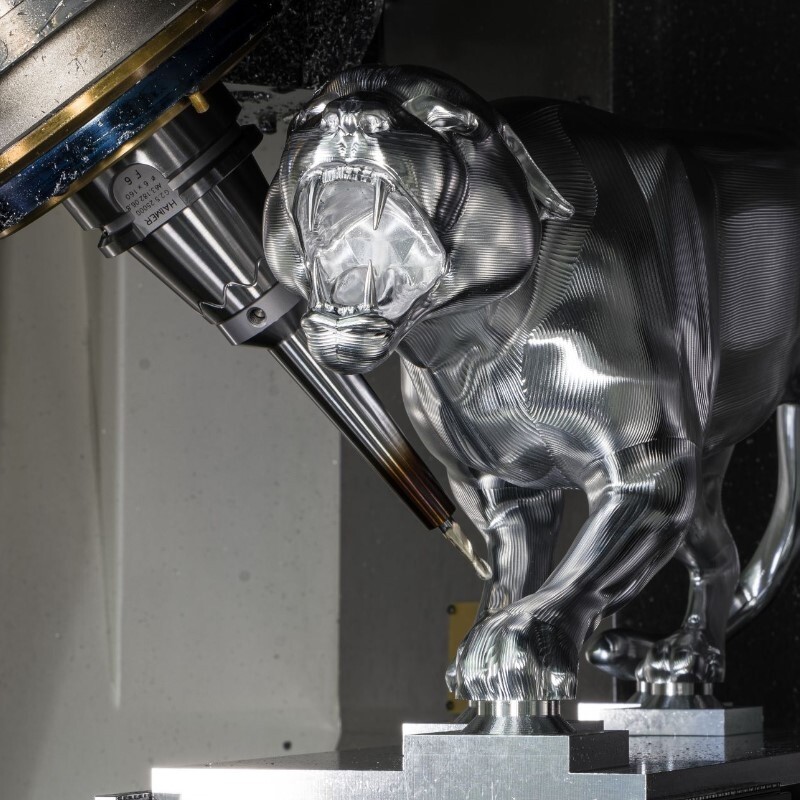

- Precise Manufacturing

We have implemented a lean manufacturing workflow that follows the ISO-2768-m and ISO-2768-c standards, specifically designed to achieve tight tolerances.

- Rigorous Inspection

We prioritize rigorous inspections throughout our production process. Our dedicated Quality Control (QC) employees conduct a comprehensive series of inspections, including material inspection, processing inspection, and finished product inspection.

Specific Practices for Quality Assurance

- Pre-production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment on your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

- In-production

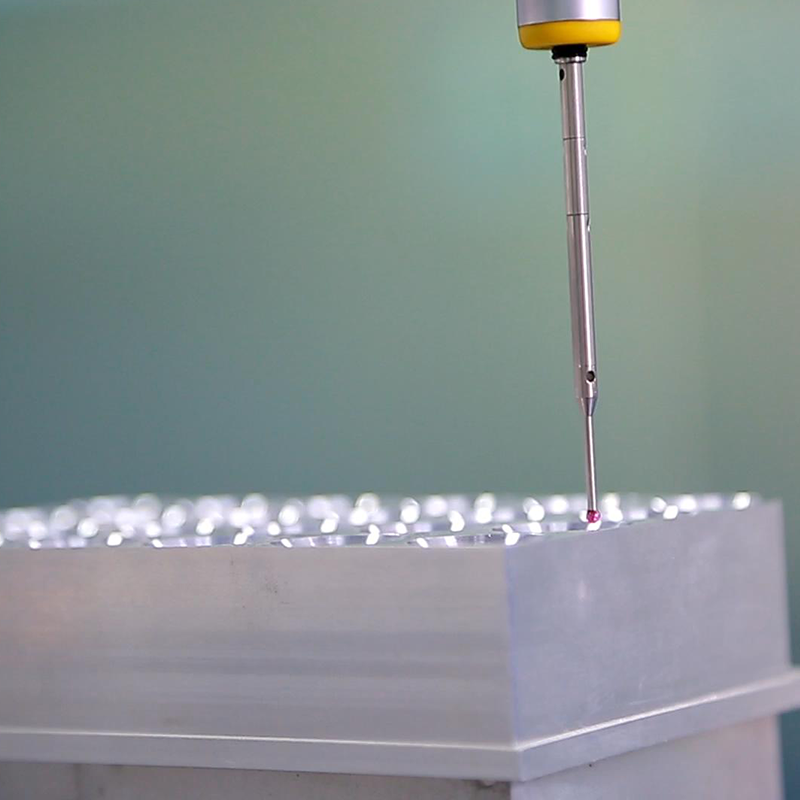

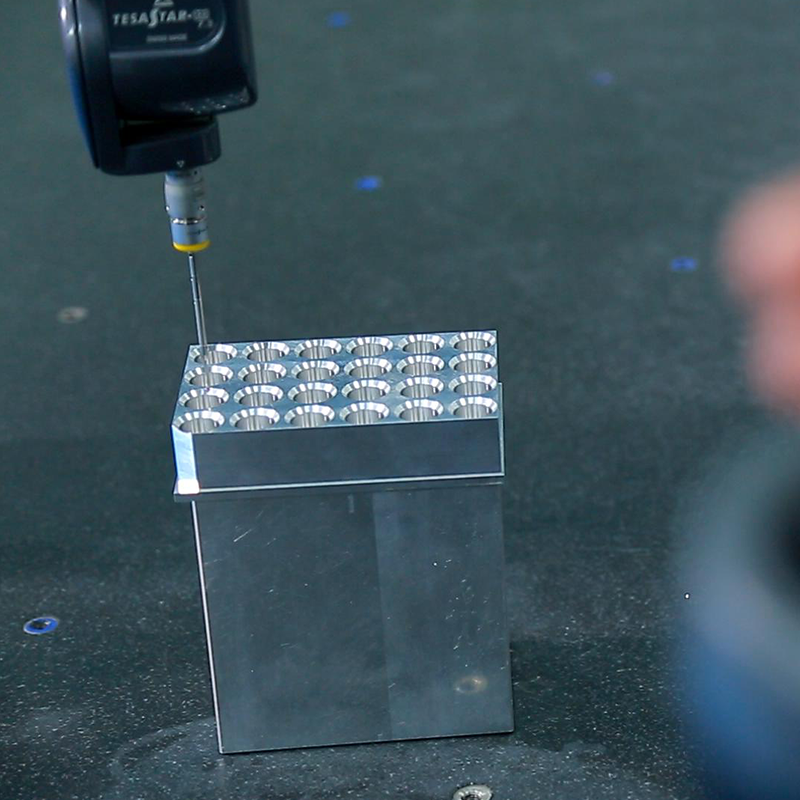

On-site inspection system

In precision machining, it is important that materials being worked on is always at the right position. With on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using on-site inspection system further helps avoids issues at the early stage, saving cost and time.

In-process quality control

At Future Parts, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

- Final production

Full-dimensional inspection report

For all orders, we provide full dimensional inspection report on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

Quality Reports

- Visual Inspection

In this stage, we confirm if the product or part meets the customer’s appearance requirements. We consider the product’s color, texture, and other physical attributes.

- Dimensional Inspection

We inspect parts with simple structures using vernier calipers, micro-caliper, and height gauges. We also use the CMM machine to measure its dimension accurately if complex products.

- Performance Inspection

We test the functionality and performance of the produced component. For instance, for parts with threadings or threaded holes, we inspect the assembly to ensure the parts fit.

- First Article Report

In this final stage of the inspection process, we provide our clients with the final inspection report. This report gives a rundown of all the inspection processes and results.

- Material Certifications

We can provide material certifications according to the customer’s request.

React Quickly and Effectively to Quality Issues

Future Parts aims to deliver exceptional prototypes and parts that fulfill your specific requirements. In the event that production fails to meet your specifications, we can process a rework or a refund. Feel free to contact with us if you come across any quality issues within 1 month of receiving goods. Let us know within five business days from receipt, and we’ll address them within 1 to 3 business days.