Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

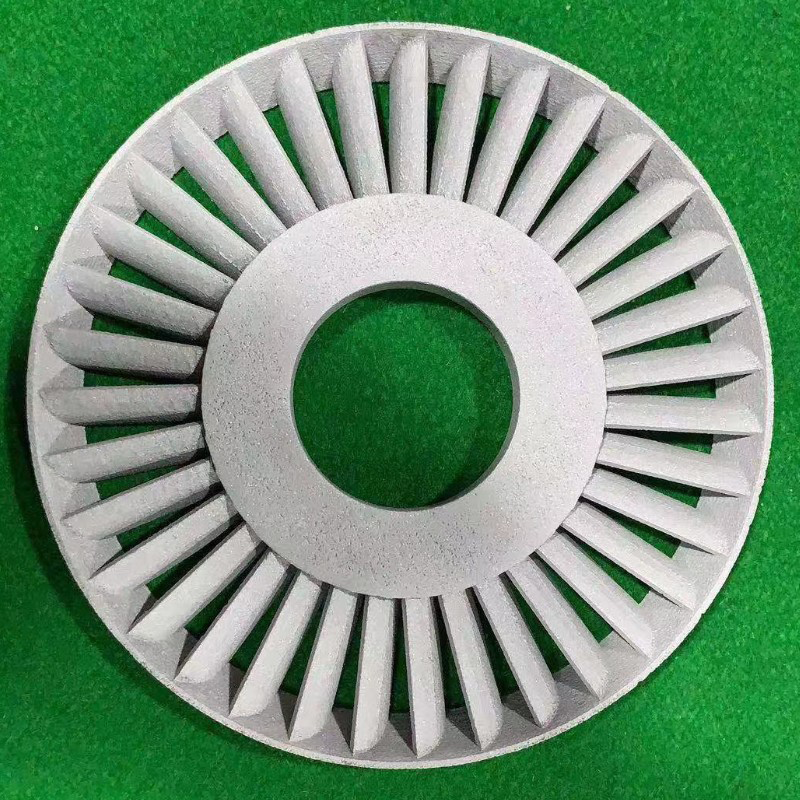

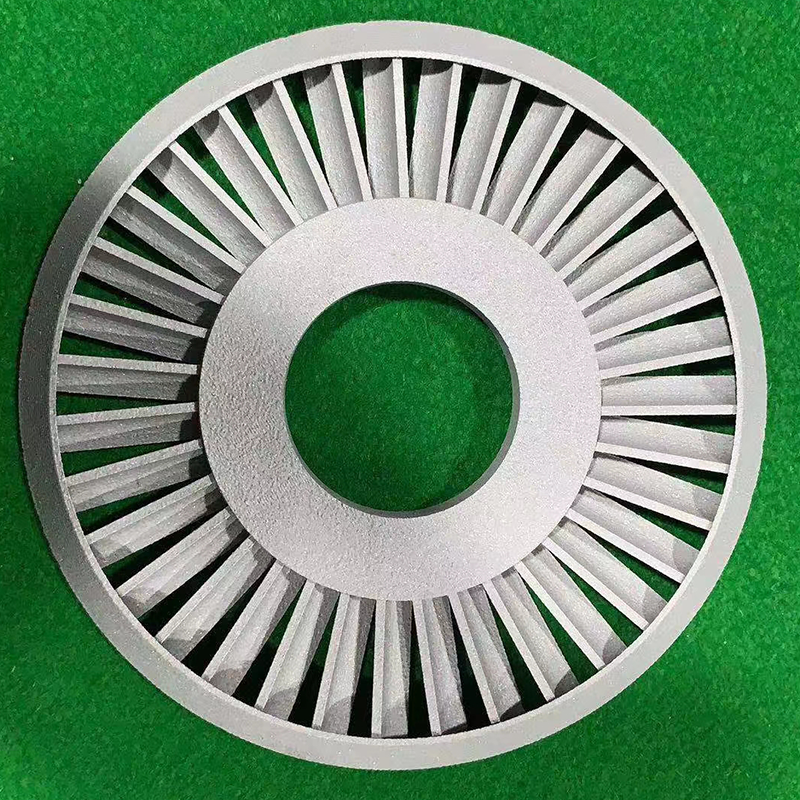

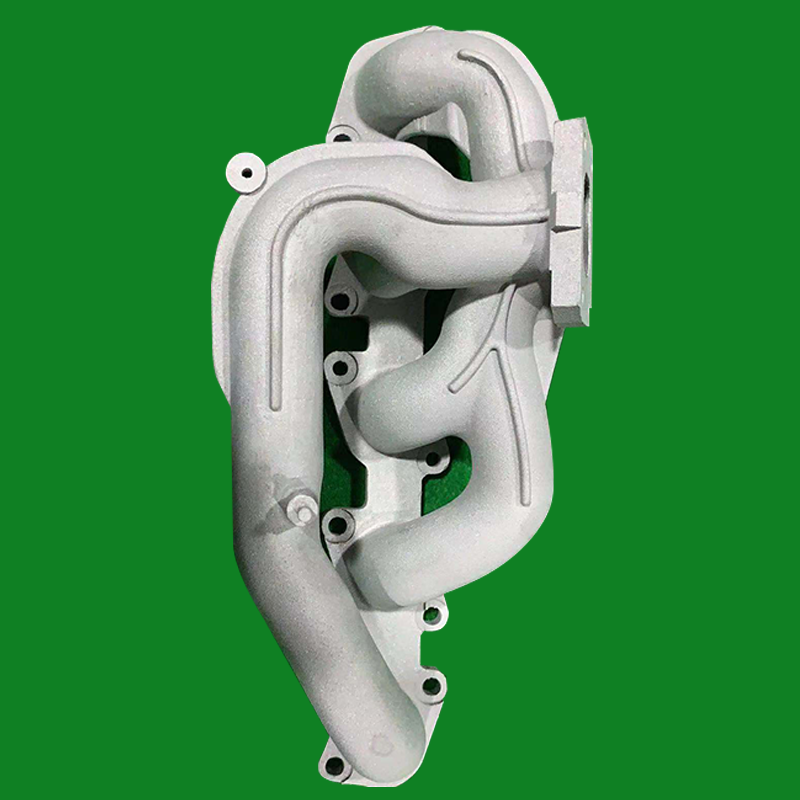

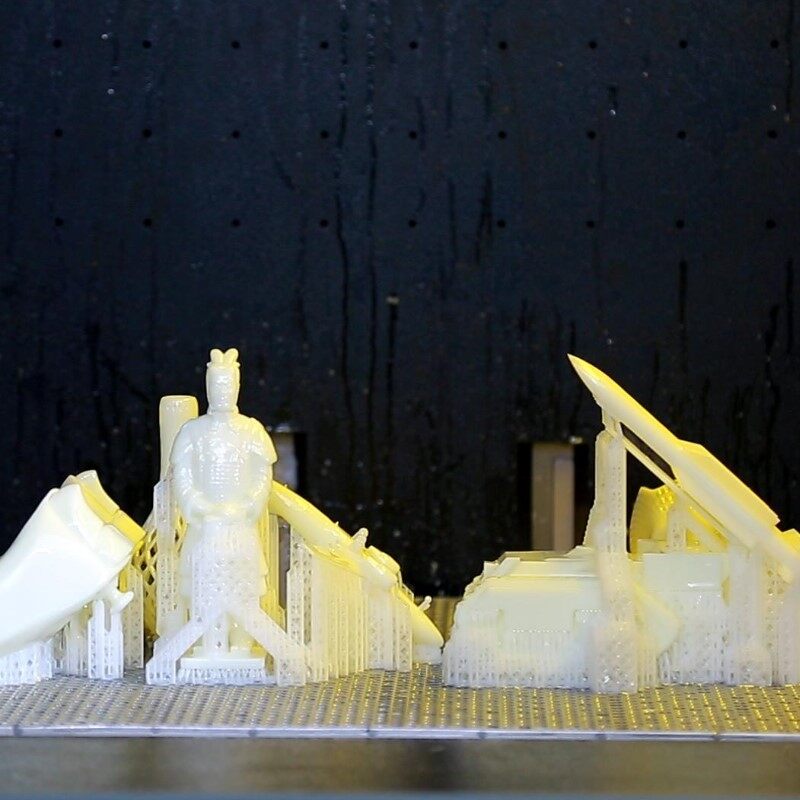

DMLS 3D Printing Service

Direct Metal Laser Sintering or DMLS is an industrial metal 3D printing technology. It is a powder bed fusion process similar to SLS, which builds parts from a range of metal materials one layer at a time by sintering metal powders together.

DMLS 3D printing is a process capable of building highly complex shapes which would be near impossible to make via other methods. This technology promises to have a massive range of applications as it improves and becomes better understood.

Specification

|

Maximum Build Size |

280 x 280 x 280 mm (11″ x 11″ x 11″) |

|

Lead Time |

3 days |

|

Resolution |

± 0.3mm |

|

Prototyping Applications |

Complex-shaped functional prototypes for testing |

|

End-Use Applications |

Low volume functional end-use parts |

Metal 3D Printing Materials

- Pure Copper

3D printing with pure copper is possible with DMLS and SLM. Copper is a malleable, ductile, and an extremely good conductor of both heat and electricity. It is ideal for heat exchangers and electrical equipment such as wiring and motors.

Appearance:Pinkish Red

- Bronze

Bronze is an affordable metal 3D printing material option. It's a copper-based alloy that resists corrosion and metal fatigue better and conducts heat and electricity better than most steels. Bronze is commonly used for sculptures, musical instruments, medals and in other industrial applications.

Appearance:Dull Gold

- Stainless Steel

Future Parts can 3D print in different grades of stainless steel. Stainless steel is strong and highly resistant to corrosion and rust, making it ideal for parts that are exposed to different elements for long periods and do not easily break.

Material Reference: FS 316L, FS 420, FS 15-5PH, FS 17-4PH

Appearance: Silver Metallic

- Titanium Alloy

Titanium alloys have high specific strength, good high temperature mechanical properties and excellent corrosion resistance. 3D printing with titanium is very precise, making it a popular material choice in the aerospace and automotive industries.

Material Reference: FS Ti6Al4V, FSTA15

Appearance: Silver Grey-White Metallic

- Aluminium Alloy

Aluminium is a cost-effective choice. 3D-printed aluminium parts are strong and light, making them ideal for the aerospace, aviation, and automotive industries.

Material Reference: FS AlSi10Mg

Appearance: Silver Metallic

- Nickel-base Superalloy

With SLM and DMLS, you can 3D print difficult-to-machine metals like Nickel-base superalloy. Nickel-base superalloys are corrosion resistant high-temperature alloys that have exceptional strength. It is typically used in aerospace, power generation, and automotive high temperature applications.

Material Reference: GH4169 Superalloy

Appearance: Metallic

Typical DMLS Finishing Options

|

|

Applicable Materials |

Colour |

Description |

|

Sanding |

All |

– |

Sanding DMLS printed parts is a good way of smoothing edges, minimizing visible layers, and getting rid of any leftover support marks. |

|

Spray Painting |

All |

Black, Pantone/RAL colours |

Sanding DMLS printed parts is a good way of smoothing edges, minimizing visible layers, and getting rid of any leftover support marks. |

|

Plating |

All |

– |

Polishing is often used to enhance the appearance of an item, create a reflective surface or prevent corrosion. |

The Advantage of product

- Efficiency

Metal printing defies traditional Design-For-Manufacturing guidelines, so designs that would typically be made in assemblies can be made in a single piece.

- Complex Geometries

DMLS and SLM produces parts that cannot be made using traditional manufacturing techniques.

- Rapid Turnaround

Metal 3D printed parts do not require tooling which reduces the manufacturing lead time from weeks to days, allowing for faster innovation and speed to market.

- Production Parts

SLM and DMLS utilizes powdered metals with strong mechanical and dynamic properties, making it perfect for end-use parts.

The Feature of product

- Additive and CNC Synergy

DMLS and SLM technologies deliver accurate parts with precision up to 0.1mm, providing a solid foundation for high-quality components.

Additive and CNC Synergy

- Additive and CNC Synergy

Additional Content: Combine the design freedom of additive manufacturing with even tighter tolerances through our in-house CNC machining services. This synergy ensures both flexibility in design and unparalleled precision.

- Multi-Axis CNC Machining

Leverage our advanced CNC capabilities with 3, 4, and 5 axis machining, enabling intricate and complex geometries while maintaining exceptional accuracy.

- CNC Turning

Employ CNC turning to achieve precision in cylindrical components, enhancing the overall accuracy and functionality of your parts.

- Wire EDM Services

Benefit from Wire EDM for precise and intricate cuts, ensuring accuracy and consistency in complex shapes and features.

- CNC Tapping

Utilize CNC tapping for accurate threading in components, contributing to the overall precision and functionality of machined parts.